On November 11, E-P Equipment’s annual Double 11 event occurred at its Smart Industrial Park in Anji. The event attracted global distributors, partners, industry experts, and media. Unlike previous years, this edition exclusively showcased mobile robots, making them the event’s central focus.

The Minimalist “EXP15 Pony” Dual-Mode Automated Transporter

At the event, E-P Equipment displayed a wide range of mobile robots, including automated guided vehicles (AGVs), intelligent stackers, and tow trucks, highlighting its technological expertise and commitment to industrial automation.

A standout product was the new EXP15 Pony, designed for simplicity. This robot, equipped with electric steering, operates at a speed of 1.5m/s, with a payload capacity of 1500kg and a turning radius of 1360mm. Tasks can be assigned with a single click, making it ideal for high-volume, point-to-point material transport.

The EXP15 Pony offers dual functionality, switching between electric and automated modes. In automated mode, workers can “teach” the robot a route with simple start and stop commands, allowing it to repeat the path autonomously. E-P Equipment aims to free workers from repetitive tasks, enabling them to focus on higher-value activities.

“We designed this entry-level product to build user confidence and satisfaction while offering a cost-effective path to intelligent transformation,” the company explained. E-P Equipment emphasizes selecting solutions based on core needs rather than blindly pursuing automation.

Beyond basic models like the Pony, E-P Equipment provides advanced solutions for diverse scenarios, covering essential material handling tasks such as stacking, transporting, and towing.

Innovation in Material Handling Modes

E-P Equipment believes mobile robots are transforming not just the method of transport but also the operational model itself. It introduced the X-Mover Smart Handling Model to address specific industry needs, combining a product, a smart solution, and tailored problem-solving for various sectors like automotive, logistics, and beverages.

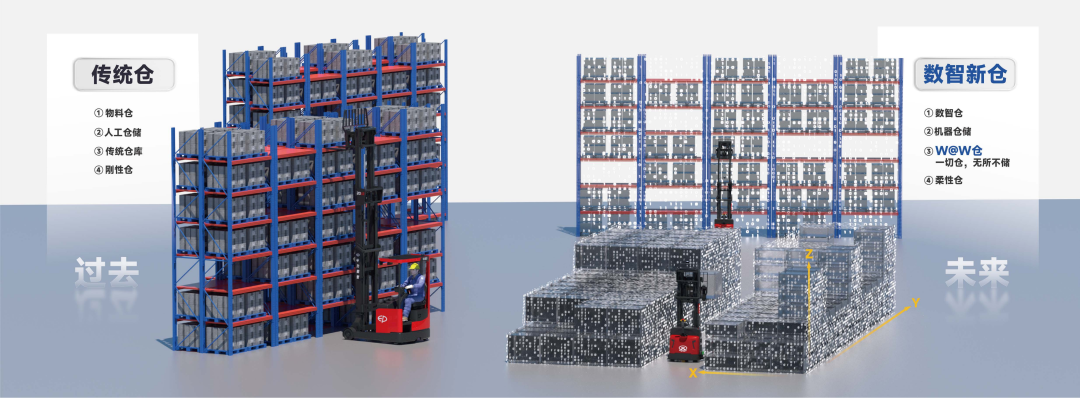

E-P Equipment also launched the “W@W Distributed Smart Warehouse” concept, dividing storage spaces into distinct categories (e.g., pallet racks, and bins) and employing intelligent stackers to enhance warehouse flexibility and efficiency.

Pioneering Group Buying for Robots

For the first time in the industry, E-P Equipment applied a group buying model during the Double 11 event. This model leverages collective buying power to secure discounts, benefiting distributors and reshaping traditional sales strategies.

“Our goal is to empower our partners with new business strategies and inspire confidence for the future,” the company stated.

As of 6 PM on November 11, E-P Equipment had recorded over 2100 robot orders, showcasing its success and growing influence in the competitive mobile robot market.

Conclusion

E-P Equipment has grown significantly in the smart logistics sector, evolving from exploratory efforts to market leadership. By focusing on demand-driven innovation, problem-solving models, and smart manufacturing, the company continues to redefine productivity and efficiency across industries.

探索者论坛-scaled.jpg)