iRAYPLE Launched the First Outdoor Counterbalanced Forklift AMR

Recently, iRAYPLE launched the first outdoor counterbalanced forklift AMR FPE150. This product uses an outdoor reinforced frame with IPX5 protection level, which can easily cope with the 1,500kg load demand; equipped with a multi-sensor fusion system, it can accurately adapt to complex scenarios such as platforms, factory areas and outdoor stacking; relying on self-developed core algorithms, it can achieve seamless connection between indoor and outdoor, and build a truly unmanned handling closed loop.

Linde Added Three Models to its Automated Forklift Series

Recently, Linde Material Handling, an expert in internal logistics solutions, added three models to its automated forklift series. According to Linde, Linde K MATIC k VNA turret forklift, Linde R-MATIC k reach forklift, and Linde L MATIC AC k counterbalanced pallet stacker equipped with cantilever forks were launched.

Both VNA forklifts and reach trucks adopt advanced reflector navigation technology and are equipped with a sensor-based fork positioning system to accurately store and retrieve standardized carriers such as Euro pallets, cages and CHEP pallets. In addition, the new models are all independently developed by Linde to achieve end-to-end coverage of core logistics processes. VNA forklifts and reach trucks can also be digitally networked with the pallet stacker series.

Brightpick Launched its First Multi-functional Warehouse Robot

Recently, Brightpick launched Autopicker 2.0. Autopicker 2.0 uses the company’s next-generation Intuition software and is a completely redesigned hardware platform, which can perform an average of 70-80 picks per hour, is comparable to the productivity of typical warehouse employees, and provides higher reliability and 24/7 operation. Compared with the first-generation model, the new Autopicker has a 50% increase in throughput per robot, thanks to a 40% increase in picking speed and a 20% increase in travel speed.

Founded in 2013, Brightpick aims to develop the world’s most advanced robotic distribution solutions. Since its establishment, it has completed multiple rounds of financing, and the total financing amount has reached USD 47 million.

YUNLY Independently Developed its Intelligent Box-type Cargo Robot

YUNLY independently developed an intelligent box-type cargo robot. The model adopts an omnidirectional mobile chassis design and has a high-precision multi-source fusion navigation system, which can flexibly adapt to the complex operation requirements of outdoor factories and indoor environments. By integrating RTK high-precision positioning, multi-line laser radar SLAM and odometer + IMU multi-sensor data, centimeter-level positioning and stable obstacle avoidance are achieved, and the navigation mode can be seamlessly transitioned to adapt to complex working conditions, ensuring reliable operation in all weather and all scenarios.

In terms of protection, the robot adopts an IP65-level dustproof and waterproof box structure, and the cargo compartment has a closed rainproof design to effectively protect the cargo from environmental influences such as rain and dust. The chassis is equipped with omnidirectional wheels, supports zero-radius steering and lateral movement, and can still efficiently transport in narrow spaces. It can realize multi-machine collaborative operation and dynamic task allocation to improve overall handling efficiency.

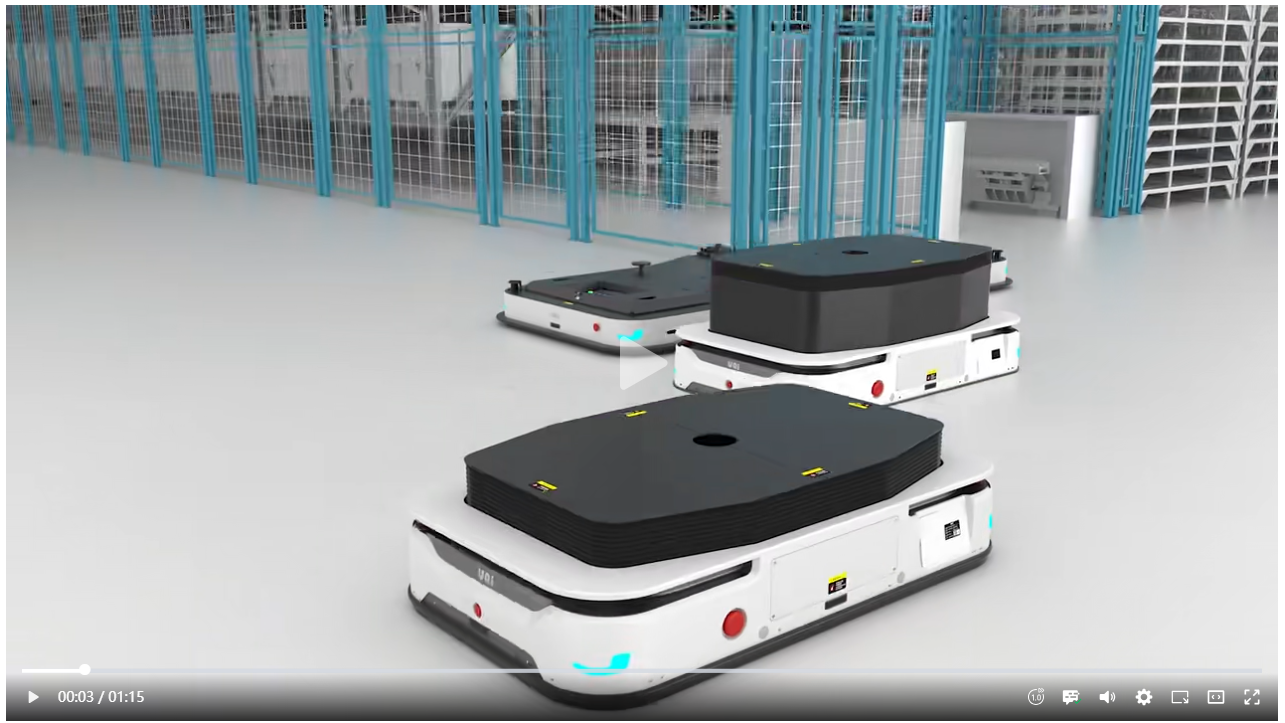

UQI Launched Wali H3000 Heavy-duty Omnidirectional Robot

On June 30, UQI launched Wali H3000 heavy-duty omnidirectional robot that is a logistics robot with a load capacity of 3,000kg and omnidirectional mobility providing a new solution for customers in the automotive manufacturing, new energy battery and other industries to build a flexible and efficient logistics model.

Wali H3000 has demonstrated breakthrough performance in multiple dimensions such as adaptability, accuracy, stability, and safety, and has adapted to more application scenarios with multiple models/configuration products such as H3000S-standard version, H3000S-high lift version, and H3000L.

Wali heavy-duty omnidirectional robot H3000 supports three modes of transportation: carrying, lifting, and traction, with an ultra-high load-to-volume ratio. It adopts the omnidirectional motion control technology to achieve free movement in any direction, uses laser SLAM-based fusion navigation and positioning technology to achieve ±5mm positioning accuracy, is equipped with a quadruple servo lifting mechanism and an adaptive suspension system to greatly improve the ability to resist off-center loads and stability, and uses multi-sensor fusion perception technology to complete 360° stereoscopic perception and flexible obstacle avoidance.

ABB Released Heavy-duty AMR

Recently, at the Automatica 2025 (during June 24 and 27) held in Munich, Germany, ABB released a series of heavy-duty products, including a compact heavy-duty mobile robot (AMR) with a load of up to 1,500kg.

This heavy-duty AMR has a compact chassis and a wheeled mobile system, with a maximum load of up to 1,500kg, and is simultaneously controlled by OmniCore™ and equipped with an AI visual navigation system. This AMR combines ground logistics load capacity and robot flexibility, and is an important fulcrum of ABB’s integration strategy in “robot + mobile + vision”.

EP 629 Released a Series of New Mobile Robots

During June 28 and 29, 2025, EP released a series of new mobile robots at the “EP Seventh Annual Innovation Conference on June 29”, including narrow channel unmanned forklifts, lateral intelligent loading and unloading forklifts, and embodied material mobile robots.

It is reported that for different height shelves in narrow channels, EP has launched forklifts that meet different heights; its lateral intelligent loading and unloading forklifts can automatically complete the unloading and warehousing of flying wing trucks with the help of laser SLAM multi-source fusion navigation technology; the embodied material mobile robot is equipped with a robotic arm for the first time, moving towards full-scene autonomous operation. This series of products is equipped with a low-precision 3D camera of thousands of yuan to replace tens of thousands of high-precision equipment models. Lightweight technology greatly reduces computing power requirements and achieves top performance with “civilian configuration”.

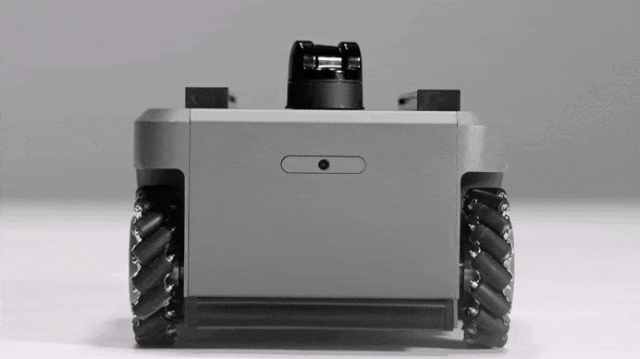

Elephant Robotics Released Mobile Composite Robot myAGV Pro

On June 30, 2025, Elephant Robotics released the mobile composite robot myAGV Pro, which is an omnidirectional steering system vehicle under Elephant Robotics. It is compatible with the lightweight collaborative robot arm ecosystem of Elephant Robotics and most general-purpose collaborative robots on the market and can complete related applications of artificial intelligence such as multi-target environmental detection and voice semantic recognition.

Note:

Logistics Automation Development Strategy & the 7th International Mobile Robot Integration Application Conference Southeast Asia will be held in Concorde Hotel Kuala Lumpur, Malaysia on 21st August 2025. Welcome to join us.

For agenda, please click https://cnmra.com/logistics-automation-development-strategy-the-7th-international-mobile-robot-integration-application-conference-southeast-asia-21st-august-2025-concorde-hotel-kuala-lumpur-malaysia/

For registration, please click https://docs.google.com/forms/d/e/1FAIpQLSdGHjpHRU0mR0_2ZlqtJpUV25s3XlIIHtkkUUfxz0W6vpBqiA/viewform?usp=header

探索者论坛-scaled.jpg)