Siasun

In 2025, as a leading Chinese robot manufacturer, Siasun, while maintaining its traditional strengths in mobile robots, was fully exploring the new track of embodied intelligence. The company launched the “Songyi” wheeled and “Songxing” bipedal humanoid robots, and established an embodied intelligence research institute. Leveraging its deep industrial accumulation, the company adhered to a pragmatic industrial approach and a dual-track strategy (wheeled and legged), targeting phased implementation in manufacturing and other scenarios. Furthermore, the company continued to deepen the integration of AI and 5G, strengthening communication and collaboration capabilities to support the efficient and intelligent operation of future multi-robot systems.

Keywords: Embodied intelligence, humanoid robots, “robot + AI”, internationalization

Geek+

In 2025, Geek+ was listed on the HKEX as the “first listed company in global AMR warehouse robots,” raising a record amount of funds, marking its entry into a new stage driven by both capital and technology. The company’s operating quality improved significantly in the first half of the year, with adjusted EBITDA turning positive, approaching the profit inflection point. Strategically, leveraging its leading global market share and commercial network, it actively extended towards embodied intelligence, launching the industry’s first warehouse scenario base model, Geek+ Brain, and an unmanned picking solution, aiming to achieve end-to-end unmanned warehousing and open up a second growth curve.

Keywords: First listed company in global AMR warehouse robots, embodied intelligence, commercial strength + global network

Hikrobot

In 2025, Hikrobot deepened its strategic transformation into an “ecosystem builder,” launching three ecosystem products, including controller kits and EasyAMR, empowering partners to lower development barriers. Its hardware continued to evolve, launching several new products such as the Forklift 2.0 and F3 Mini, improving load capacity, efficiency, and scenario adaptability. While maintaining steady revenue growth, it deepened industry applications and accelerated its global layout, driving the industry from single-point competition to collaboration.

Keywords: Ecosystem strategy, hardware evolution, collaborative solutions, globalization

Hai Robotics

The revenue of Hai Robotics in 2025 increased by approximately 50% year-on-year, with a global cooperative robot scale exceeding 30,000 units, and overseas market growth of approximately 60%. The core highlight is the launch of the minimalist and efficient “goods-to-person” HaiPick Climb, achieving rapid deployment through unique “shelf-climbing” technology. The company is accelerating its globalization, building smart manufacturing bases in Malaysia and other locations, increasing production capacity tenfold, and collaborating with over 400 ecosystem partners. Channel sales account for 80% of total sales, establishing a robust growth model.

Keywords: Performance growth, HaiPick Climb, global delivery, high flexibility, modularity

iRAYPLE

In 2025, iRAYPLE continued to deepen the collaborative innovation of machine vision and mobile robots, providing customers with full-stack services covering products, solutions, and AI, helping manufacturing enterprises upgrade intelligently through technology empowerment and scenario implementation. Simultaneously, the company was comprehensively advancing its internationalization strategy, participating in global exhibitions and ecosystem activities, and actively building a cooperation network. Furthermore, the company planned to change its proposed listing location from Chinese mainland to the HKEX in July 2025.

Keywords: “Machine Vision + Mobile Robots”, full-stack services, IPO

HCGZ Intelligent

In 2025, Hangcha Group fully entered the field of embodied intelligence, reconstructing its intelligent logistics landscape through the acquisition of Guozhi Robotics, and driving the company’s transformation from a traditional forklift manufacturer to a provider of comprehensive intelligent logistics solutions. In October, Hangcha released its first “X1 Series” humanoid robot, targeting industrial applications. Currently, Hangcha’s strategy focuses on industrial applications, using data to drive technological development, and is committed to creating specialized humanoid robots with practical operational capabilities, building a new intelligent logistics ecosystem.

Keywords: Wheeled humanoid logistics robots, M&A, data-driven, algorithms

EP

In 2025, EP accelerated its transformation with embodied intelligence as its core: it released the super-humanoid embodied picking robot “X-mover,” embodied loading and unloading technology, and a full-scenario loading and unloading automation solution and a small-parts digital intelligent solution—the Digital Intelligent Flying Warehouse—built upon this technology, constructing an unbreakable core competitive barrier and leading the industry’s digital transformation; simultaneously, it built the “Warehouse @Anywhere (W@W) Distributed Digital Intelligent New Warehouse” system, opening up the “in-store-out-store” logistics link, and completing its transformation from an equipment manufacturer to a provider of intelligent handling solutions and ecosystem services.

Keywords: Embodied intelligence, digitalization, full-scenario loading and unloading, off-site logistics

Linde

Linde’s automation business in the Chinese market was expected to grow rapidly in 2025, maintaining its leading position with complete solutions covering hardware, software, solutions, and services. Its self-developed MyMA software platform and E’tricc scheduling system constitute the core of its intelligence, integrating AI and digital twin technologies. By adhering to three key strengths of globally unified standards, mature platforms, and a comprehensive service system, it deeply cultivated industry scenarios such as pharmaceuticals and manufacturing, achieving reliable deployment.

Keywords: “Industry + Scenario,” full-stack solution, software platform, global standards

KUKA AMR

In 2025, KUKA focused on mobile robot product iteration and scenario deployment, launching the lightweight KMP 250P robot, the fully self-developed KMR iico 12i composite robot, and other lightweight models, while also iterating and upgrading existing products. The company made progress in the field of embodied intelligence, jointly launching the world’s first “intelligent agent factory” with Midea at its Jingzhou factory. In the first half of 2025, KUKA’s mobile robot business achieved strong growth, with revenue nearly doubling year-on-year; domestic self-developed product shipments exceeded 1,000 units; and the company accelerated its expansion into overseas markets, aiming for overseas sales to account for over 50%, strengthening its global competitiveness.

Keywords: Full-stack self-developed, composite robot, intelligent agent factory, overseas expansion

NTI

In 2025, NTI addressed the mature stage of industry competition with a dual-track strategy of “re-examination” and “re-launch”. On the product side, it focused on launching omnidirectional, high-level, and loading-scenario unmanned forklift series to improve its intelligent equipment matrix; simultaneously, it proactively deployed AI and embodied intelligence integration technologies. On the market side, while deepening its domestic presence, it actively expanded into overseas markets (Southeast Asia, Japan, Europe) with high-quality products. The planning of a new production base in Shenzhen laid a solid foundation for its future capacity expansion and full-scenario coverage strategy.

Keywords: Embodied intelligence, AI, unmanned forklift, overseas expansion, capacity improvement

Gen-song

In 2025, Gen-song focused on technological breakthroughs and capacity expansion, commencing construction of a base with an annual production capacity of 10,000 intelligent equipment units. At the CeMAT exhibition, it globally debuted its “last link” intelligent loading solution and wheeled humanoid robot, extending application scenarios from warehousing to general operations. Simultaneously, it accelerated its global expansion, planning to establish a subsidiary in the United States to deepen international expansion through localized operations.

Keywords: Intelligent vehicle assembly solution, wheeled humanoid robot, AI, global expansion

YOUIBOT

On September 26, 2025, YOUIBOT officially submitted its listing application to the HKEX, aiming to become the “first listed company in mobile manipulators.” Based on 2024 revenue, YOUIBOT is the world’s largest industrial mobile manipulator company and also ranks first among mobile manipulator companies in China. YOUIBOT primarily addressed pain points in two major scenarios: industrial logistics and inspection and maintenance, and had deep roots in the semiconductor and energy chemical industries. YOUIBOT strived to reconstruct the industrial intelligent ecosystem with its “One-Brain-Multi-Form” architecture. Its industrial embodied intelligence system with “One-Brain-Multi-Form” includes a highly generalized industrial embodied intelligence model (“one-brain”) and multiple forms of embodied intelligent robots with perception, decision-making, and interaction capabilities (“multi-form”).

Keywords: IPO on the HKEX, mobile manipulator, “One-Brain-Multi-Form”, embodied intelligence, industrial scenarios

IPLUSMOBOT

In 2025, IPLUSMOBOT continued to deepen its core technologies in mobile robots, accumulating profound expertise in omnidirectional heavy-duty applications, especially achieving remarkable results in large-scale desktop omnidirectional applications and customized omnidirectional heavy-duty applications. Simultaneously, the company continued to deepen its presence in key regions such as Japan, South Korea, Southeast Asia, and North America, promoting the localization of products, services, and the industrial ecosystem; and, driven by scenario-based approaches, launched products and solutions for customers in different countries. Furthermore, the company proactively deployed embodied intelligence technology and, in December, jointly released two wheeled humanoid robots with the Zhejiang Humanoid Robot Innovation Center.

Keywords: Internationalization, embodied intelligence, wheeled humanoid robot, omnidirectional heavy-duty technology

HUAXIAO

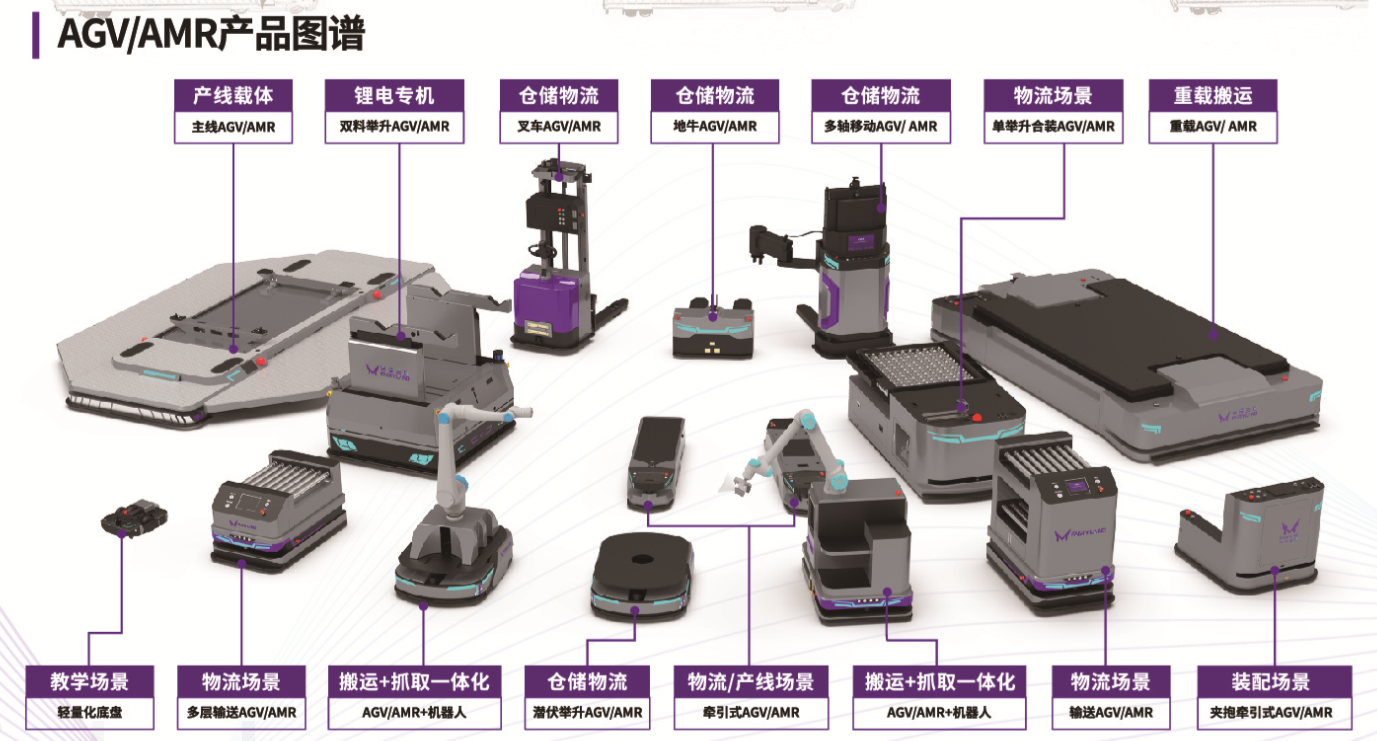

In 2025, Huaxiao strived to become a healthy and sustainable, industry-leading, product-centric intelligent solutions provider. In terms of product matrix, Huaxiao focused on four major series: traction-type, lifting, heavy-duty, and autonomous forklift, emphasizing standardized and modular design. Technologically, Huaxiao continuously invested in SLAM navigation, motion control, heavy-duty loading, and cluster scheduling, gradually forming leading capabilities in multi-machine linkage and 100-ton heavy-duty transfer. Facing globalization trends, Huaxiao followed leading clients overseas, aiming for “out-of-the-box” solutions in overseas projects, creating a “white goods” product model. Furthermore, in 2025, Huaxiao collaborated with key domestic universities, leading clients, and AI industrial model companies to jointly develop embodied intelligent robot products targeting challenging industrial scenarios.

Keywords: “Non-standard customization,” “Go overseas with leading clients,” “out-of-the-box,” “Three major industries + N scenarios + productization + ultimate delivery”

Fairyland

In October 2025, Fairyland completed a B-round financing of over 100 million yuan, receiving strategic investment from Wuhan Junshan New City Technology Investment Group. The company adhered to a focused strategy, deeply cultivating the automotive vertical field while successfully expanding into new industries such as tobacco and military. Facing industry cycles, the company had shifted towards steady expansion, focusing more on healthy operations. At the forefront of technology, the company was actively developing embodied intelligence, researching and developing wheeled humanoid robots, and promoting software and hardware integration through collaboration, committed to the intelligent implementation of industrial scenarios.

Keywords: Financing, embodied intelligence, wheeled humanoid robots, focus, steady expansion

GYRO

In the first half of 2025, GYRO achieved explosive growth, with orders exceeding twice that of the previous year. The company officially established a subsidiary in Japan, building a global network of four major operation centers. Leveraging its third-generation narrow-body omnidirectional AMR, it precisely addressed pain points in the semiconductor industry, with monthly production capacity leaping to 500 units. Strategically, it deepened its presence in the Japanese, Korean, European, and American markets, strengthening its competitive advantage through “localized services + AI intelligent control,” and was committed to the unmanned and flexible upgrading of semiconductor factories.

Keywords: Global semiconductor layout, deep collaboration, capacity expansion, flexible logistics scheduling, AI

GALAXIS

In 2025, GALAXIS, an expert in intelligent logistics robots, released its new generation of very-narrow aisle forklift mobile robots, the “VFR series,” using groundbreaking technology to solve pain points in warehouse space utilization and efficiency. Simultaneously, the company continued its IPO process on the HKEX, consolidating its leading position in the field of warehouse automation with its full-stack solutions and global layout.

Keywords: IPO on the HKEX, very-narrow aisle, globalization

HELI EFORK

In 2025, Heli Intelligent Institute, Heli Technology, EFORK, and Jianghuai Zhixing completed their integration, operating under the unified “HELI EFORK” brand, forming an organizational structure of “one institute and three companies.” The company’s annual order growth was 50%, revenue growth was 60%, and overseas market orders achieved a breakthrough growth of 200%. In terms of product and technology layout, it clearly focused on complex scenarios such as high-bay warehousing, dense storage, and extreme environment applications; it developed multiple scenario-based mobile robots: cold storage version + explosion-proof version + wine-specific AGV, and a fully forward-moving AGV adapted for long materials, large tonnage, and narrow aisle operations. Furthermore, it achieved breakthroughs in multiple new industries, new scenarios, and new applications, successfully delivering several benchmark demonstration pilot projects, covering fields such as tires, high-precision instruments, ceramics, and fertilizers.

Keywords: Integration and collaboration, high-growth performance, ecosystem alliance, product innovation

RobotPhoenix

RobotPhoenix is a Chinese industrial robot company specializing in the design, R&D, manufacturing, and commercialization of industrial robots, providing comprehensive robot solutions, and deeply cultivating light industrial application scenarios. RobotPhoenix possesses a robot architecture built around the four core functions of skilled workers—”brain,” “eyes,” “hands,” and “feet”—to achieve intelligent decision-making, environmental perception, precise control, and autonomous movement. In 2025, it officially launched its IPO on the HKEX, aiming to strengthen R&D, production capacity, and overseas expansion. On November 17, it officially released its first humanoid robot, “Hongjun,” officially launching its attack on the “flexible unmanned territory” of industrial automation.

Keywords: IPO on the HKEX, “brain, eyes, hands, and feet,” overseas expansion, humanoid robot

VMR

VMR focused on product innovation and ecosystem integration in 2025. In the first half of the year, it released a hidden forklift product—a latent forklift—and an omnidirectional mobile robot chassis; in the second half of the year, it launched the world’s first humanoid robot head module, OmniHead. VMR’ multi-brand robot scheduling system, VMR-RCS, successfully achieved unified scheduling of 33 heterogeneous robots at a high-end manufacturing customer site, improving efficiency by 49% and demonstrating its open and collaborative platform capabilities.

Keywords: Multi-brand scheduling, latent forklift, embodied intelligence

LOGIANT

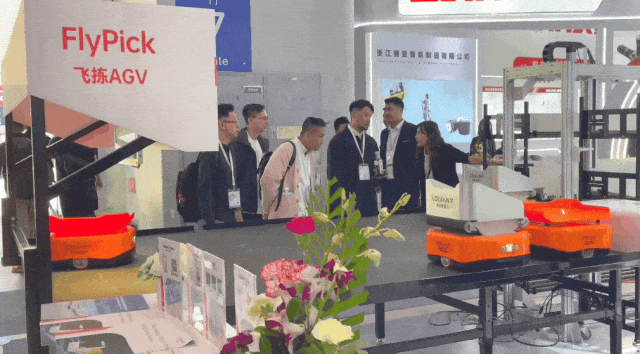

LOGIANT focused on full-scenario logistics solutions. In 2025, its B2B intelligent warehousing project for a well-known South Korean cosmetics cross-border e-commerce company utilized 53 latent AGVs + 2 three-way forklift AGVs and related solutions to create an efficient, precise, and automated intelligent distribution center. In October, the company showcased its latest technological achievements in innovative logistics across all scenarios at CeMAT ASIA 2025. The core of this system is the new generation FlyPick flying-picking robot independently developed by LOGIANT. Leveraging its deep technological foundation and industry service capabilities, LOGIANT has built a full product line matrix covering indoor and outdoor unmanned tractor units, flying-picking robots, mixed-site scheduling platforms, RCS, WMS, etc. Its products and solutions have served industry giants such as SF Express, BYD, and China Post.

Keywords: Full-scenario innovative logistics, FlyPick flying-picking robot

LINDIN

In 2025, relying on its extensive team experience and “customer-first” philosophy, LINDIN achieved a steady leap in performance, becoming a core supplier for leading companies such as CATL. The company continued to expand into overseas markets and deepened its presence in the new energy, military, and heavy-duty AGV fields, while maintaining a prudent approach to industry trends and adhering to a sustainable development path prioritizing profits.

Keywords: Customer first, performance leap, overseas expansion, heavy-duty AGV

The Second Global Unmanned Forklift Application Scenario Competition & the Material Handling and Sorting Challenge for Embodied Wheeled Humanoid Robots 2026 will be held by CMRA in May. Building upon the unmanned forklift competition, a wheeled humanoid robot track will be introduced for the first time, responding to the industry’s real-world needs for embodied intelligent application scenarios and further building a bridge connecting technological innovation and industrial applications.

探索者论坛-scaled.jpg)