The number of entrants into the humanoid robot and embodied intelligence markets continues to grow. In just a few days, three major Chinese logistics equipment giants, such as Hangcha, EP, and Gen-song, have announced their cross-industry investments in embodied intelligence, a intensive initiative that has garnered industry attention.

Unmanned forklifts, AMRs, and ASWs, once booming, are now merging with “humanoid” forms. Has logistics opened up new opportunities for humanoid robots, or are humanoid robots becoming the next growth engine for the logistics industry?

Hangcha: Wheeled humanoid robots for logistics

As a leading domestic industrial forklift manufacturer, Hangcha Group has been continuously increasing its investment in the intelligent logistics sector since 2018. Through the establishment of Hangcha Intelligent, the company has gradually built an integrated solution encompassing intelligent logistics equipment and systems, including AGVs/AMRs, stackers, four-way shuttles, and carousel racks, continuously improving its hardware, software, and system integration capabilities.

At the same time, Hangcha Intelligent is continuously strengthening the core development of software algorithms, data systems, and large-scale models. On the one hand, it actively collaborates with system suppliers across various industries to deeply understand customer pain points and core needs in real-world projects. On the other hand, it leverages its practical experience from hundreds of projects annually to continuously optimize its proprietary software systems. It is reported that its independently developed software systems collect actual customer usage data, using this data to continuously optimize algorithms and enhance system intelligence, ultimately achieving end-to-end data management from equipment to scenarios.

With the evolution of technology, Hangcha has begun to turn its attention to cutting-edge humanoid robots. In February of this year, Hangcha and Guozi Robotics jointly visited the Haichuang Humanoid Robot Industry Innovation Center in Yuhang District, Hangzhou, to discuss the application prospects of humanoid robots in light-load, low-precision, and highly flexible scenarios. This move signaled Hangcha’s expansion into the “humanoid + logistics” business.

In July of the same year, Hangcha Intelligent acquired Guozi Robotics, further strengthening its mobile robot product portfolio and technological innovation capabilities. Guozi Robotics’ advanced algorithms and software capabilities will greatly enhance Hangcha’s R&D capabilities and global market delivery capabilities in the intelligent logistics field, creating strong synergies with its existing AGV business. From unmanned forklifts to logistics robots, and now to the upcoming humanoid robot, Hangcha has established a relatively comprehensive smart logistics strategy. It is within this strategic framework that Hangcha Group unveils its first humanoid robot at CeMAT ASIA 2025.

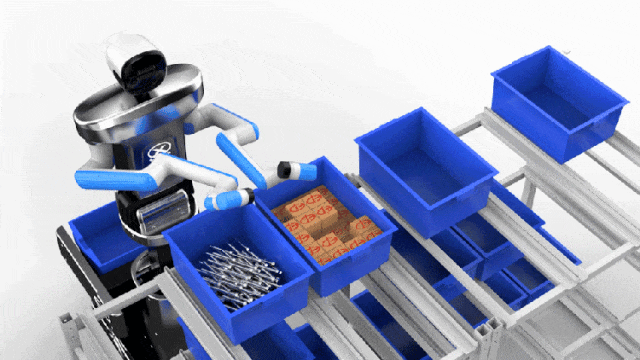

This wheeled logistics humanoid robot is designed specifically for industrial scenarios and can handle a variety of tasks, including bin handling, stacking, and depalletizing. Compared to traditional logistics equipment, its movements are more similar to those of humans, enabling flexible replacement and human-robot collaboration, providing a practical path for humanoid robots to enter the front lines of industry. This is not only a leap forward for Hangcha Group in cutting-edge technological exploration, but also a powerful footnote for the industry’s practical application in the wave of embodied intelligence.

Gen-song: Wheel-legged Humanoid Robot

As a leading domestic company in intelligent logistics systems and equipment manufacturing, Gen-song has accumulated a solid technical foundation in AGVs, ASW systems, and intelligent conveying equipment. Building on this foundation, it is now moving towards a new stage of “humanoid” and “universal” embodied intelligence.

At the end of 2024, Gen-song officially launched the development of its “wheeled humanoid handling robot” project and disclosed progress at multiple investor events and financial reports. According to public disclosures, the project is based on the company’s proprietary AGV control system and visual navigation algorithms, combined with humanoid joint structure design and AI decision-making systems. The goal is to create a next-generation robotic platform that combines flexible movement and human-robot collaboration.

In the application of embodied intelligence, Gen-song emphasizes “intelligent handling” and “flexible logistics” as core breakthroughs. The company believes that with the increasing complexity of manufacturing and warehousing scenarios, relying solely on traditional AGVs or unmanned forklifts will no longer be able to meet diverse operational needs. Therefore, embodied intelligent robots will become a key vehicle for bridging automation and intelligence.

The “wheel-legged humanoid robot,” exhibited at CeMAT ASIA 2025, is Gen-song’s latest achievement in the field of embodied intelligence. It is reported that the robot deeply integrates three-dimensional perception and multimodal AI technologies, aiming to break the boundaries of traditional robotic applications in logistics.

The company will also simultaneously release an intelligent solution for the “last link” of inbound logistics, an intelligent robotic “goods-to-cart” system. This solution has already been deployed in leading overseas customer scenarios, helping a global drinking water giant double its overall efficiency. While significantly improving labor productivity, it has also reduced in-plant operation and maintenance costs by approximately 30%. It also supports full-process intelligent loading and unloading operations for multiple carts and multiple pallets with mixed loads.

From system integration to embodied intelligent carriers, from automated equipment to humanoid robots, Gen-song is transforming its role in the intelligent logistics system from “equipment manufacturer” to “intelligent solution provider” through product innovation and application expansion.

EP: Super-humanoid Embodied Intelligent Robot “Kangaroo”

As a leading company in China’s electric warehousing and handling equipment sector, EP has recently accelerated its development of embodied intelligent robots, entering a new phase centered on “versatility + intelligence + full-scenario application.”

EP’s development history demonstrates its long-term technological accumulation and a clear transformation strategy. In 2012, the company launched the “Little King Kong” series of lightweight handling equipment, driving the industry’s transition to electrification. In 2016, it pioneered lithium battery technology, driving the shift from oil to electricity. Since 2020, the company has entered the field of intelligent robotic handling equipment, ushering in a new era of integrated automation and intelligence.

Driven by the rise of AI and embodied intelligence, EP has proposed a three-tiered intelligent strategy: “product-level, model-level, and system-level,” restructuring its Industrial Logistics 4.0 technology ecosystem and focusing on full-chain innovation in “intelligent loading and unloading + unmanned transportation.” The goal is to connect the three major links of “on-site material handling, intelligent warehousing, and off-site transportation” to build a highly flexible and intelligent next-generation logistics closed-loop system.

On June 29, 2025, EP will officially launch the “Embodied Material Moving Robot” at its annual Innovation and Development Conference. This product, equipped with a robotic arm for the first time, marks the company’s transition from traditional handling equipment to embodied intelligence capable of “full-scenario autonomous operation.”

At the same time, EP is accelerating its embodied intelligence development through capital investment and ecosystem collaboration. EP has invested in XYZ Embodied AI, a robotics company known as a “dark horse” in embodied intelligence, to strengthen collaborative innovation in core embodied intelligence technologies and application scenarios. Furthermore, in July 2025, the company announced a 478 million yuan investment in the “Digital Intelligence Logistics Equipment Project,” which will cover intelligent handling equipment, unmanned ground handling equipment for aviation, and key components for embodied robots.

Notably, EP will launch its superhuman embodied intelligent robot, “Kangaroo,” globally during the 2025 “Double Eleven” shopping festival. Designed specifically for warehouse picking, this robot’s appearance differs from a traditional humanoid form, resembling a “large kangaroo” capable of movement, bending, and carrying.

Kangaroo is said to possess multimodal intelligence capabilities: its brain can recognize various parts and packaging; its hands can grasp, attract magnetically, and pneumatically; its body can rise, turn, and bend; its feet can move; its pouch can lift and move; and its swarm can collaborate. This design breaks the limitations of traditional embodied robots due to their humanoid structure, prioritizing efficiency and flexible operation in complex warehouse environments.

From “Little King Kong” to “Kangaroo,” EP’s technological path demonstrates its transformation from a single equipment manufacturer to a provider of embodied intelligent systems. Leveraging its long-standing expertise in chassis, electronic controls, motors, and system integration, EP is building an embodied intelligent ecosystem with a more “industrialized” mindset, allowing robots to truly integrate into production sites and serve the entire logistics chain.

Behind the Collective “Humanoid Creation” of Logistics Equipment Giants

This wave of logistics equipment giants, such as EP, Hangcha, and Gen-song, entering the market is not a mere spur of the moment, but rather a natural consequence of industry cycle changes.

Over the past decade, intelligent logistics equipment such as unmanned forklifts, AGVs, and AMRs have driven automation upgrades in warehousing and manufacturing. However, this wave of benefits is gradually reaching its peak. With fragmented scenarios, rigid processes, and limited room for efficiency improvement, companies are beginning to rethink the next generation of productivity. Embodied intelligence and humanoid robots have become a new technological focus. They possess “generalized adaptability” and can perform diverse tasks in complex, non-standard scenarios, becoming a key path to solving the “last ten meters” automation challenge.

From a supply chain perspective, logistics equipment companies already poss core hardware capabilities such as chassis, motors, transmissions, and sensing, making them a natural fit within the humanoid robot industry chain. Forklift manufacturers’ long-standing expertise in structural design, safety redundancy, battery management, and manufacturing systems provides the underlying capabilities for “industrialization” of humanoid robots. This enables them to enter the field of embodied intelligence with lower trial-and-error costs and more mature engineering systems, moving beyond “prototyping” to mass production and practical implementation.

At the same time, advances in large AI models and multimodal technologies are also moving the “humanoid” from concept to reality. Robots are no longer simply a collection of mechanical movements, but are increasingly equipped with the capabilities of understanding, decision-making, and interaction. In logistics scenarios, this means robots can autonomously identify materials, dynamically plan routes, and collaborate with humans, which is an intelligent leap unattainable by traditional AGVs.

Therefore, the entry of logistics companies into the market is not only about seeking a second growth curve, but also about restructuring the industry’s logic: from “automation” to “intelligence,” and from “standard task machines” to “general-purpose task bodies.” In the future, when humanoid robots truly enter warehousing, loading and unloading, and production lines, it will not only be a turning point for the robotics industry, but also a rebirth for the logistics equipment industry.

——————————————————————————————————————————————————————————————————————————————

On December 5, EP and Gen-song will attend the 3rd Ecological Conference for Embodied Intelligence Humanoid Robot Scenario Application 2025 held at Hefei Platinum Hanjue Hotel, further sharing their embodied intelligence and humanoid robot solutions. At the same time, Quadruped Robot Scenario Application Development Blue Book 2025 will be released. Anyone who would like to attend the conference or get the blue book, please feel free to contact us via info@cnmra.com.

探索者论坛-scaled.jpg)