Singapore-based Botsync Launched First AMR

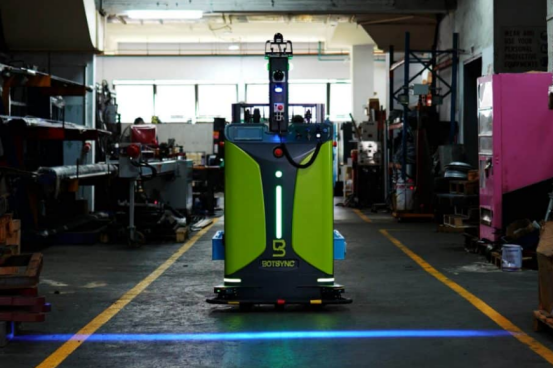

To drive logistics automation in brownfield factories, Singapore-based Botsync recently launched its first fork-type autonomous mobile robot (AMR): the MAG1400 Fork. Designed for rapid deployment in existing production and warehousing facilities, this product automatically handles and stacks pallets through layered adaptability, helping customers achieve efficiency improvements and operational modernization.

As the company’s first fork-type AMR, the MAG1400 Fork features a floating fork mechanism, enabling multifunctional pallet handling, stacking, and transport capabilities, making it suitable for brownfield warehouses and manufacturing plants. It emphasizes easy deployment and compatibility with existing forklift paths, eliminating the need for re-laying tracks or modifying rack structures, minimizing implementation costs and lead times.

Founded in 2017, Botsync is a startup focused on developing industrial-grade autonomous mobile robots (AMRs). Headquartered in Singapore, it operates extensively in manufacturing-intensive regions such as India and Southeast Asia and continues to expand globally. Its products feature “plug-in automation,” emphasizing the ability to achieve intelligent transformation without major modifications to existing buildings or processes.

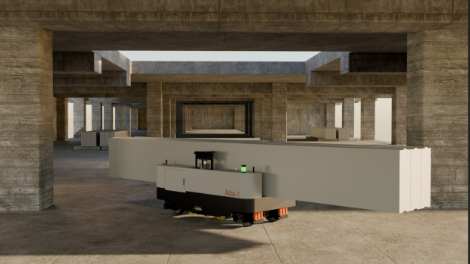

ZOEROBOT Released Atta-1 Handling Robot

On September 3, ZOEROBOT released the Atta-1 handling robot. The Atta-1 weighs 600kg and has a maximum load capacity of 2,100kg, enabling contactless handling throughout the entire process. Its four-wheel independent travel and steering, along with a zero turning radius, allows it to handle a wide range of scenarios, including residential construction, public buildings, factories, construction elevators, 90-degree turns, and slopes. In addition to prefabricated wall panels, it can also handle large, heavy building materials such as floor tiles, glass, electromechanical modules, and building material packages.

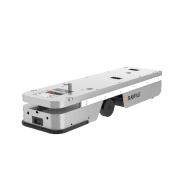

iRAYPLE Unveiled Two AMRs

Leveraging its deep technical expertise and extensive industry experience, iRAYPLE has developed a “Dual-Engine Towing AMR Solution”, the lightweight latent towing AMR Q100 and the heavy-duty front-towing AMR T300. These solutions address the core challenges of flexible handling, large-load collaboration, and stable operation in the automotive manufacturing industry.

The lightweight latent towing AMR Q100 utilizes multiple navigation methods, including laser, texture, and QR code, and supports 120-second rapid battery swapping, saving charging time. Furthermore, it intelligently identifies the vehicle’s position, enabling docking with ±5mm precision. It integrates multiple laser and vision sensors for autonomous obstacle avoidance, detecting obstacles as low as 5cm.

The heavy-duty front-towing AMR T300 supports 2D/3D laser SLAM navigation, as well as auxiliary navigation methods such as visual line tracking. It also supports automatic hooking and unhooking. Furthermore, it integrates laser and 3D vision for three-dimensional obstacle avoidance. Equipped with a full servo control system, it offers precise control and stable reliability.

Hyundai Wia of South Korea Launched New Logistics Products, Entering the Mobile Robot Market

Hyundai Wia of South Korea recently officially announced its entry into the mobile robot market with the launch of its new logistics robot product line. This represents a significant expansion of the company’s downstream automated logistics equipment, in addition to its components manufacturing and machine tool systems. This product line is expected to serve applications requiring high-frequency movement and flexible motion, such as warehousing, distribution, and e-commerce.

The new logistics robot series includes two categories: platform-type logistics handling robots and AGVs/AMRs, offering both large-scale handling and free-route navigation capabilities. Platform robots are primarily used for handling heavy pallets or components within factories or warehouses; AGVs feature path planning, obstacle avoidance, and remote monitoring capabilities to adapt to complex logistics environments. Product specifications include a maximum payload of 1,500 kg, a battery life of approximately 8 to 10 hours, fast charging support, and a modular design for adjustable load and power configurations.

Hyundai WIA, a core parts and industrial equipment manufacturer under the Hyundai Motor Group, has long focused on the manufacturing and precision machining of machine tools, engine parts, and automatic transmission components. Its expansion into the mobile robot market signals a strategic move towards further expansion and diversification into logistics automation and intelligent equipment.

Germany Company igus to Launch Collaborative Palletizing Robot

Recently, German company igus Inc. announced that it would showcase its new economical palletizing collaborative robot, the Fairino FR20, at PACK EXPO 2025 in Las Vegas, USA. This product is designed to provide a more accessible automated palletizing solution for manufacturing, warehousing, and logistics applications.

The Fairino FR20 is a collaborative robot with a 20 kg payload capacity, an 1,854 mm reach, and six degrees of freedom. Its intelligent control system ensures stable and accurate pallet stacking, making it ideal for high-throughput logistics, manufacturing, and warehousing environments. The launch of the Fairino FR20 marks a significant expansion for igus into the low-cost, high-entry market in packaging automation and warehouse logistics. For users seeking automation upgrades but facing budget or space constraints, the FR20 offers a balanced performance and cost-effective option.

Raymond Launched RBS26-F Lithium-Ion Stacker

Raymond, a subsidiary of Toyota Material Handling, recently introduced the Raymond® RBS26F Stacker, a new lithium-ion battery stacker in its Basics series. Designed for handling and stacking sliding pallets, boxes, containers, and floorless platforms, the product is positioned as an economical and practical material handling tool, targeting customers in warehousing, distribution, manufacturing, retail, and home centers. The RBS26-F can lift objects to heights between 72 and 114 inches and handle loads ranging from 1,480 to 2,600 pounds, making it highly adaptable for medium-load and medium-to-high stacking applications. It features low-speed, creeping modes, and dual thumb controls for precise load movement in tight spaces, reducing the risk of mishandling.

UK startup Humanoid Launched Dual-arm Mobile Robot

Humanoid recently announced the launch of the HMND 01 Alpha, a dual-arm mobile manipulator for industrial use. The London-based robotics and artificial intelligence developer mentioned that it had developed the robot in just seven months.

The robot stands 220 cm tall and can reach speeds of 7.2 km/h. Using its dual arms, it can carry payloads of up to 15 kg, and it can lift even more weight when objects are close to its body. Its reach extends from the floor to 2 m and its shelf depth reaches up to 60 cm, enabling it to pick items directly from ground or elevated storage locations. The HMND 01 can handle repetitive, physically demanding tasks such as picking and sorting goods, feeding machines, kitting, loading and unloading inventory, and supporting packaging and fulfillment.

Haosheng Developed and Launched Ultra-Heavy-Duty 300-Ton AGV

Hangzhou Haosheng Electric Vehicles Co., Ltd. recently completed performance testing of its ultra-heavy-duty 300-ton AGV and delivered it to its customer’s site. This AGV, 10 meters long and 5.2 meters wide, is custom-designed for the production and transfer of motor nacelles in the wind power industry.

This AGV technology incorporates over a dozen invention and utility model patents, including Haosheng’s intelligent vehicle networking, energy control systems, and automated logistics vehicles, as well as several proprietary software copyrights. It is equipped with top-tier components such as reducers, lithium batteries, LiDAR, sensors, and polyurethane wheels, along with Haosheng’s proprietary chassis and control systems.

X-Mover Revealed its First 1.5-Ton Double-Sided Forklift Narrow Aisle Stacking Robot

Recently, X-Mover launched the XAN151, a 1.5-ton double-sided forklift narrow aisle stacking robot designed specifically for narrow aisles and unlocking space potential. This innovative robot features dual-sided intelligent forklifts for picking up cargo, eliminating steering requirements and using its body as the aisle width. Its narrowest aisle is only 1740mm, saving approximately 50% of storage space. Equipped with LiDAR and visual camera fusion positioning technology and employing a learning-based adaptive lateral control algorithm, it achieves high-precision positioning, ensuring safe and efficient high-altitude operations in narrow aisles.

———————————————————————————————————————————————————————————————————————————

The 2024-2025 Global Mobile Robot Industry Development Report, compiled by China Mobile Robot (AGV/AMR) Industry Alliance (CMRA) and New Strategy Mobile Robot Industry Research Institute (NSRI), has been released, which covers sales amount and volume, popular application segments, popular product categories, analysis of each industry chain segment, representative global market players, and future development trends.

For details of the report, please click https://cnmra.com/release-of-the-2024-2025-global-mobile-robot-industry-development-report/.

Moreover, this report just costs $398. If you need it, please feel free to contact us via info@cnmra.com.

探索者论坛-scaled.jpg)