Robot Phoenix Released Camel50 Container Transferring Unit (CTU) and S100 AGV

Robot Phoenix breaks through technical barriers through independent research and development, optimizes production processes and reduces manufacturing costs, and finally reduces the price of Camel50 CTU and S100 AGV to 10,000 yuan, breaking the price ceiling of high-end equipment. The Camel50 CTU is specially developed to solve the demand for CTU for the AirBot released last year, aiming to enable customers to quickly build AirBot solutions. The running speed can reach 4m/s and the lifting can be completed within 4s.

The S100 AGV has the “install and use” feature, which subverts the traditional AGV “customized design + long-term deployment” model. Its own unique on-board system does not require additional configuration of the scheduling system, which greatly simplifies the use process.

Sany Robotics Launched A7 Smart AGV

Recently, Sany Robotics launched a major innovative product, the A7 Smart Transporter, during the 2025 Changsha International Construction Equipment Exhibition. This “smart AGV” combines intelligent driving and manual control. It can carry out long-distance and short-distance transport inside and outside the factory and can cope with complex scenarios. It solves the problem of traditional AGVs losing positioning due to uneven ground, and has good passability and adapts to rugged roads. This product has three breakthrough advantages: First, it can be “out of the box” and run independently, and can be put into production in as fast as 5 minutes; second, it is equipped with advanced 3D environmental perception system and self-developed algorithms, which can quickly generate optimized paths; finally, the core components adopt IP67 automotive-grade protection, providing the industry’s first 5-year or 10,000-hour ultra-long warranty for the core three-electric, setting a new benchmark for safety and reliability.

Syrius Launched AMR FlexPilot

Recently, Syrius launched a new generation of intelligent delivery AMR FlexPilot. FlexPilot is designed for high-security and high-confidentiality scenarios such as hospitals, laboratories, and banks. It accurately responds to the internal logistics needs of “sensitive items” and “critical tasks”, and focuses on improving the intelligent automation and professional Standardization of medical-grade logistics.

FlexPilot is deeply integrated with hospital HIS, SPD and other management systems through AI drive, easily realizing safe, accurate, efficient and clean intelligent scheduling and automatic delivery, truly realizing the full process of “planning-scheduling-delivery-handover-leaving traces” automated operation, helping medical institutions to achieve process upgrades and efficiency leaps while ensuring the safety of sensitive items.

Standard Released DARWIN-01

On May 28, Standard officially released the DARWIN-01 industrial embodied robot. DARWIN-01 has a high degree of scalability and freedom, can cope with a variety of working conditions, and can fold the fuselage for rapid deployment. The whole machine is equipped with a variety of sensor matrices, which can achieve 360°×360° dynamic perception and build a full range of security perception networks. Its 23 degrees of freedom enable it to have the ability to convert between crouching and standing to meet different work needs. The load capacity of the dual-arm collaborative operation can exceed 10kg, which can easily complete various tasks. It supports the replacement of a variety of dexterous hands and industrial mechanical grippers, and can easily adapt to different task scenarios such as heavy handling and precision grasping. The bottom adopts an omnidirectional steering wheel design, and the moving speed exceeds 2m/s, ensuring efficient and flexible mobility. The battery charge-discharge ratio reaches 1:12, supporting automatic charging and battery replacement functions, greatly reducing downtime. In addition, the whole body is equipped with a VR remote control system, combined with AI training data collection and algorithm iteration, to continuously improve system performance.

IPLUS MOBOT Released SN Series Single Fork Arm Intelligent Forklift

On May 29, IPLUS MOBOT launched the SN series single fork arm intelligent forklift, which is designed for transporting low and narrow material trucks. It has the characteristics of compact structure, flexible and efficient, safe and reliable. At present, it has been successfully applied in many fields such as 3C, semiconductors, automotive parts, and food packaging.

The SN series single fork arm intelligent forklift does not need to modify the existing low material truck, and can be directly forked and docked, which is economical and convenient, and has strong adaptability; it has a compact model size and high passability, whether it is a space-constrained storage area or a dense production line, it can easily cope with it; it adopts laser SLAM+vision+IMU fusion navigation method, combined with multiple safety protections, to ensure the safety of people, vehicles and objects in the process of human-machine mixed traffic.

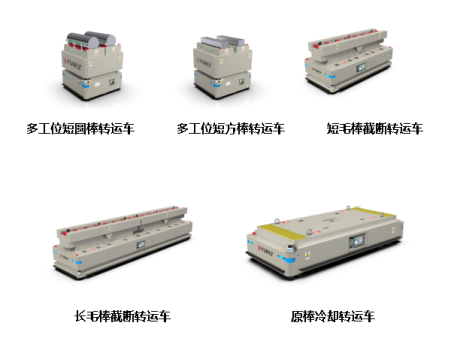

YUNLY Launched a Variety of Multi-station Intelligent Handling Robots

Recently, Wuxi YUNLY Robot Technology Co., Ltd. launched a variety of multi-station intelligent handling robots developed independently. This series of handling robots adopt omnidirectional mobile chassis technology, multi-station automatic loading and unloading design, laser radar + visual QR code + inertial combined navigation method, which greatly improves space utilization and transportation efficiency, and reduces labor costs, cargo loss rate and safety risks in the production process.

Ankuny Released Pallet Truck T16EA

T16EA is a pallet truck with a compact structure, flexible movement and efficient control, which can accurately complete the handling of goods in a narrow space. The walking and steering full-step servo actuator has precise movement and quick response, and the drive floats + cylinder pressurization increases the load capacity of the vehicle while ensuring the stability of the vehicle, and supports fork customization.

As a professional AGV body enterprise, Ankuny Intelligent Equipment Co., Ltd. has a full range of trucks, stackers, counterbalance trucks, and forward truck bodies, and provides non-standard customization services to serve the vast number of automation companies.

Beacon Robot Released BR-F15P Forklift

The BR-F15P forklift is suitable for the automated transfer and handling of Chinese character chuan-shaped pallet goods between different cargo locations. The maximum load can reach 1,500kg, the lifting speed is fast, and the lifting height is 95mm. It is widely used in scenarios such as rapid turnover of workshop production materials, storage racks, and rapid turnover of pallets. It assists in managing the flow of materials on the production line, stacking and storing pallet goods, and improving the efficiency of goods flow.

Beacon Robot unmanned forklift adopts laser navigation and positioning, without the need to modify the on-site environment. It has complex control and scheduling functions such as map construction, path planning, automatic charging, automatic operation, traffic control, coordinated docking, equipment linkage, and cluster scheduling. It can be seamlessly connected with systems such as WMS/WCS to realize intelligent and automated operations of on-site logistics.

Note:

Logistics Automation Development Strategy & the 7th International Mobile Robot Integration Application Conference Southeast Asia will be held in Concorde Hotel Kuala Lumpur, Malaysia on 21st August 2025. Welcome to join us.

For agenda, please click https://cnmra.com/logistics-automation-development-strategy-the-7th-international-mobile-robot-integration-application-conference-southeast-asia-21st-august-2025-concorde-hotel-kuala-lumpur-malaysia/

For registration, please click https://docs.google.com/forms/d/e/1FAIpQLSdGHjpHRU0mR0_2ZlqtJpUV25s3XlIIHtkkUUfxz0W6vpBqiA/viewform?usp=header

探索者论坛-scaled.jpg)