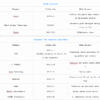

According to TianYanCha.com, on May 28, Shanghai Kepler Robot Co., Ltd. (hereinafter referred to as “Kepler”) completed Pre-A+ round of financing, and the amount of financing was not disclosed. The investor in this round, Shanghai Jijun Investment Technology Service Partnership (Limited Partnership), was jointly initiated by Pudong Venture Capital and Zhangjiang Venture.

Kepler Robot Financing History

This round of financing was only one month away from the official announcement of the previous round of financing. On April 23, Kepler completed the Pre-A round of financing. Investors include Zhangke Yaokun Fund, as well as well-known companies such as VEICHI and Keli Sensing.

It is reported that Kepler is committed to creating industry-leading blue-collar humanoid robots. Its humanoid robot Forerunner K2 “Bumblebee” (hereinafter referred to as K2 “Bumblebee”) recently appeared at the top conference in the field of robotics ICRA, and received widespread attention and praise overseas.

The Forerunner K2 has a hardware configuration of 175cm in height, 75kg in weight, and 52 degrees of freedom in the whole body. The computing power of the whole machine reaches 100 TOPS. It is equipped with independently developed planetary roller screw actuators and precision rotary power rotary actuators, and has four core capabilities: high load, long endurance, high-precision control and high cost performance. At present, the robot has also entered the automobile factory for practical training and testing.

Landing in SAIC-GM: Charging for 1 hour and working for 8 hours in a row

In April this year, Kepler Robot and SAIC-GM conducted multiple rounds of real-life training to jointly test the actual landing capabilities of its general humanoid robot Forerunner K2 in the industrial field, and simultaneously released practical training and test videos.

In the training, the Forerunner K2 easily completed many complex processes such as sewing inspection, metal stamping parts feeding, and large metal parts handling with its 30kg load capacity of both arms, 8 hours of continuous working performance after charging for 1 hour, and millimeter-level operating accuracy.

In the sewing inspection link of quality inspection, Kepler’s self-developed dexterous hand was equipped with 25 force contacts and six-dimensional force sensors, enabling the Forerunner K2 to simulate the delicate perception and precise control of human workers, and skillfully use the inspection equipment to complete the sewing inspection task; in the metal stamping part feeding link, K2 used 11 degrees of freedom dexterous hands to flexibly grasp metal parts of different sizes and accurately complete material positioning to ensure the smooth progress of subsequent stamping processes.

In the handling operation, facing large-sized and heavy-loaded automotive parts, K2 realized multi-machine collaborative operation through the KeplerBrain brain-like system™, and efficiently completed lifting, handling, positioning and other actions, further verifying its actual operation ability in the front line of industrial production.

High ROI solutions to promote the intelligent manufacturing industry

The slowdown in population growth and the increasing trend of population aging have driven the society’s demand for humanoid robots to continue to rise. In this round of training, Kepler Forerunner K2 demonstrated strong endurance and excellent load performance, far exceeding the industry’s common 2-4 hours of endurance, perfectly matching the high-intensity operation requirements of the “two-shift” production rhythm of the manufacturing industry.

It is worth mentioning that the volume purchase price of the basic version of the Kepler humanoid robot is only USD 30,000. According to actual operation calculations, the investment recovery period is about 1.5 to 1.8 years, providing a set of high ROI solutions that are both practical and economical for companies promoting intelligent manufacturing.

Humanoid robots are widely regarded as one of the most transformative tracks in the current science and technology field, and are expected to reshape future production and lifestyles. As a technological pioneer in this field, Kepler Humanoid Robot focuses on the research and development of industrial-grade blue-collar robots, and always adheres to the product concept of “creating actual productivity in industrial scenarios”.

This training cooperation with SAIC-GM is another in-depth verification of Kepler Humanoid Robot’s industrial landing capabilities, and also marks its solid steps in promoting the industrialization and application of humanoid robots.

Note:

Logistics Automation Development Strategy & the 7th International Mobile Robot Integration Application Conference Southeast Asia will be held in Concorde Hotel Kuala Lumpur, Malaysia on 21st August 2025. Welcome to join us.

For agenda, please click https://cnmra.com/logistics-automation-development-strategy-the-7th-international-mobile-robot-integration-application-conference-southeast-asia-21st-august-2025-concorde-hotel-kuala-lumpur-malaysia/

For registration, please click https://docs.google.com/forms/d/e/1FAIpQLSdGHjpHRU0mR0_2ZlqtJpUV25s3XlIIHtkkUUfxz0W6vpBqiA/viewform?usp=header