Crown Launched WJ 50 Series Compact Electric Pallet Truck

Crown Equipment Corporation recently launched the new WJ 50 series compact electric pallet truck. Featuring an extremely short body, high maneuverability, and efficient energy consumption, this product is designed for high-frequency material handling tasks in confined environments, representing another innovation from Crown in the field of short-distance material handling.

The WJ 50 series is Crown’s most compact powered pallet truck to date, designed to help users maintain high efficiency in confined spaces. Its most prominent feature is its extremely short head length, combined with an optimized steering mechanism, allowing the truck to easily operate in truck rear-end positions, lifting platforms, or ultra-narrow aisles. Official data shows that the series has a maximum load capacity of 3,300 pounds (approximately 1.5 tons), balancing the need for small size with high load capacity.

Jungheinrich Unveiled New Brand AntOn with PTL 1.5 Pallet Truck

Jungheinrich AG recently announced the launch of its new brand, “AntOn by Jungheinrich.” This brand launch marks a further extension of its product structure and brand portfolio, signifying a new multi-layered, multi-brand phase in its global strategy.

The first product launched is the PTL 1.5 pallet truck. The PTL 1.5 has a rated load of 1,500 kg and is suitable for everyday handling scenarios such as light warehousing and truck loading/unloading operations.

The PTL 1.5 is a compact pallet truck measuring 1,550 x 560 x 1,230 mm. Optional accessories include stabilizers for uneven surfaces and replacement batteries to extend full-load operating time. This product features powerful lithium-ion technology, reducing charging time, extending service life, and lowering maintenance costs.

Keenon Robotics Released S300 Heavy-Duty Intelligent Handling Robot

Recently, Keenon Robotics released its new S300 heavy-duty intelligent handling robot, which boasts a 300kg load capacity and features superior load-bearing capacity, high intelligence, and extreme flexibility.

The S300 is equipped with 3D vision, dual LiDAR, and multiple emergency stop buttons, enabling real-time environmental perception. Even in complex pedestrian and vehicle traffic scenarios, it can anticipate and brake in milliseconds, achieving zero collision risk. Furthermore, it incorporates VSLAM technology, quickly building a high-precision map upon startup, with routes and task points flexibly adjustable via the interface.

Hikrobot Launched Four New Mobile Robots

On October 23, Hikrobot held its 2025 Mobile Robot Product Launch – Hardware Product Special Session online. Four new products were released, including the Forklift 2.0, the new generation F3 Little King Kong FMR, Q3S Latent Lifting AMR, and the new generation STU CTU.

The new Hikrobot Latent Forklift 2.0 significantly improves load capacity, space utilization, and loading/unloading efficiency, and adds a 1.5T load capacity model; the new generation F3 Mini Forklift Robot, through platform architecture upgrades and highly integrated and modular design, achieves a 30% reduction in overall wiring harness and a 25% reduction in unit components; the Q3S Latent Lifting AMR can achieve unobstructed operation with an industry-leading 125mm thinnest body. The Q3S can carry a 600kg load and travel efficiently at a speed of 2m/s; the new generation STU CTU adopts a bidirectional telescopic two-stage lifting mechanism, adaptable to various actuators such as clamping, hooking, and lifting, adapting to more scenarios.

Tonglida Unveiled New Mobile Composite Robot

On October 23, Tonglida launched a new mobile manipulator, empowering upgrades in industries such as logistics, 3C manufacturing, automobile, and photovoltaics. This product features a wide variety of execution structures, including drive, side-shift, cantilever, gripping, and telescopic mechanisms. It offers rich navigation modes, supporting QR code, LSLAM, VSLAM, and color-coded navigation. The maximum operating speed reaches 1.2 m/s, supporting seamless switching between multi-vehicle collaboration and single-vehicle operation modes. Secondary docking accuracy reaches ±2 mm. It can be used in various scenarios such as docking, handling, sorting, and automated loading and unloading.

Robotize and NordModules Revealed Autonomous Mobile Robot

On October 21, Robotize and Nord Modules announced a strategic partnership and jointly launched their first jointly developed product—the Nord Quick Mover 260 module based on the GoPal P35 autonomous mobile robot. This powerful combination integrates state-of-the-art AMR technology with modular, plug-and-play intelligent transport solutions, bringing revolutionary progress to internal logistics automation.

AutoStore Launched New Warehouse Automation Product Series

AutoStore, a leading global provider of intelligent order fulfillment technology, launched a new product portfolio in the fall of 2025, aiming to solve the multiple challenges facing the warehousing and logistics industry through more advanced technologies.

In this new product launch, AutoStore focuses on “AutoCase” as its core product, providing a new solution for high-demand warehouses. This product automates the storage, retrieval, and counting of entire cases, seamlessly integrating with traditional piece-picking processes to maintain high throughput and storage efficiency during peak periods. Simultaneously, the innovative “FlexBins” technology enables a single storage grid to accommodate diverse case sizes for the first time, not only increasing storage density but also supporting the complete handling of more SKUs, providing greater flexibility and reliability for the logistics industry.

Cotex Unveiled CP15 Simplified and System Versions

Recently, Cotex launched two versions of its CP15 pallet handling robot. The simplified CP15, a ready-to-use intelligent handling robot, lowers the barrier to automation to a new low—its affordable price of 36,999 yuan, coupled with its robust capabilities of “5-minute deployment and all-day operation,” makes it the top choice for small factories and old warehouses undergoing transformation. The system version of the CP15 fully demonstrates its comprehensive capabilities of “basically covering all handling scenarios” and its advantages in deep collaboration with industrial systems.

HyperLeap Revealed HyperSort Robot Sorting Robot

On October 27, HyperLeap unveiled its new generation HyperSort Agent logistics intelligent agent, which is not a combination of individual devices, but a holistic robotic collaborative system designed around the concept of “Agent.” The solution includes several core components: the HyperSort Arm (a robotic arm for feeding packages), the HyperSort Robot (a sorting robot), and the HyperSort Wall (a sorting and seeding machine). It provides standard solutions for order sorting, parcel sorting, shelving sorting, and return sorting in scenarios such as e-commerce warehouses, B2B store warehouses, and express sorting centers, enabling rapid replication and stable, easy-to-use solutions for general industry scenarios.

KUKA Launched its New Cobot

Recently, KUKA AMR released its new cobot, the KMR iico 12i, which is entirely self-developed and manufactured by KUKA AMR, achieving integrated multi-functional control and a 12kg payload capacity, easily handling industrial logistics and other industry scenarios. Utilizing AI multimodal fusion navigation, it achieves millimeter-level precise positioning.

Megbot-AMR Released New Generation Four-Way Pallet Truck

On October 28, Megbot-AMR released its new generation four-way pallet truck. Xu Qingcai, General Manager of Megbot-AMR, stated, “This product embodies our commitment to ‘borderless warehouse automation,’ redefining industry standards for stability, safety, and efficiency through three major technological breakthroughs.”

Furthermore, Megbot-AMR’s three technological breakthroughs include a matrix laser protection system, an intelligent dual-vision system, and a full-gear walking structure. These three technological upgrades collectively result in the new generation four-way pallet truck’s superior overall performance, indicating its greater value in scenarios such as dense storage, flexible manufacturing, and intelligent warehousing.

GALAXIS Unveiled Ultra-Narrow Aisle Forklift Mobile Robot

On October 28, GALAXIS released a new member of its VFR-CC series of ultra-narrow aisle forklift mobile robots—the VFR-CC9. This not only marks another technological leap for GALAXIS in the field of high-bay warehouse automation, but also demonstrates its R&D strength and innovation speed as a leading domestic intelligent warehouse robot company.

This series of robots boasts exceptional compatibility, handling various pallet configurations with ease, including zigzag, grid, and double-sided pallets. Its maximum lifting height reaches an astonishing 9.3 meters.

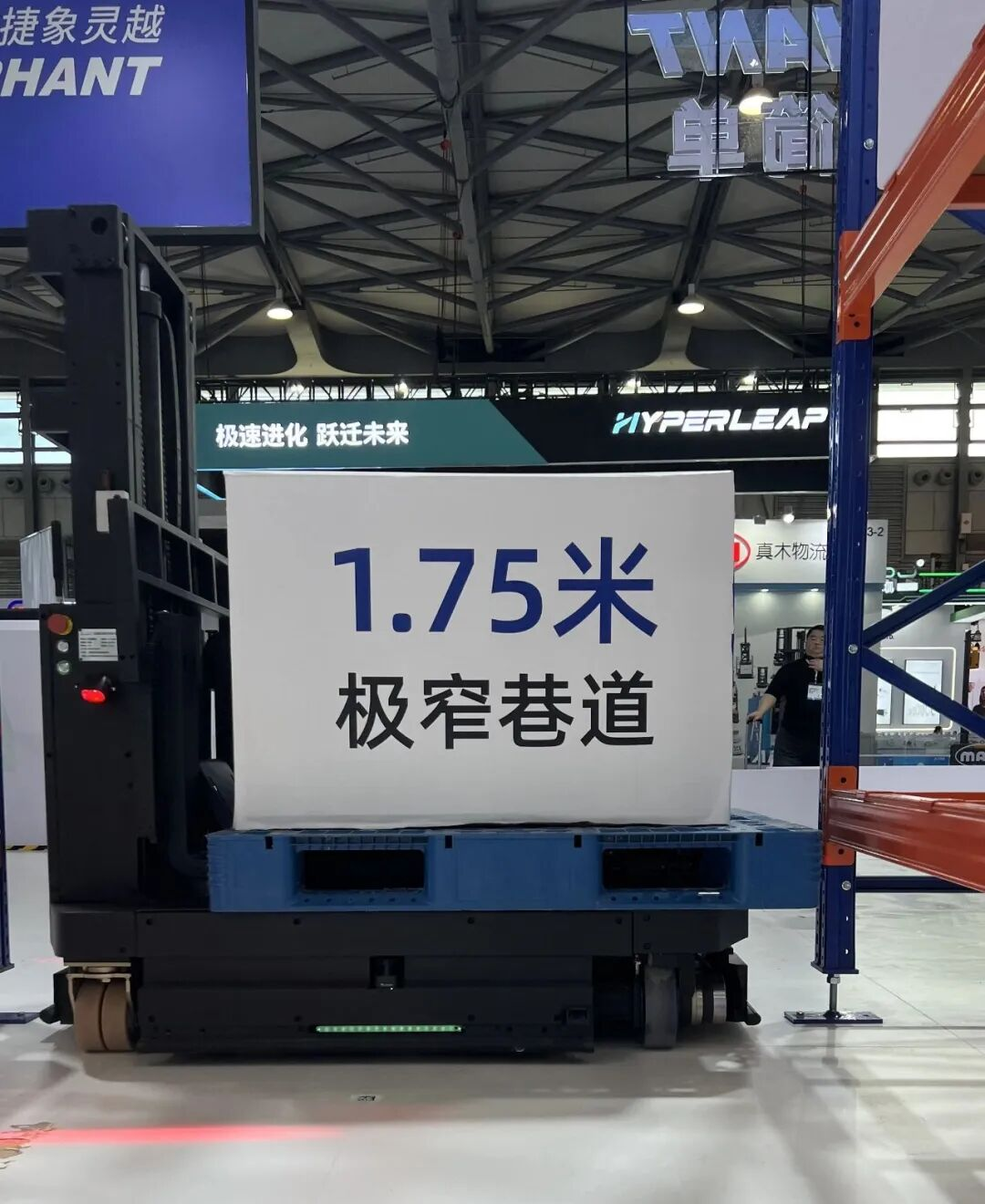

J-Elephant Launched Two VPR FK Series Automated Warehouse Pallet Robots

Recently, J-Elephant made a stunning debut with the world’s first VPR FK series automated warehouse pallet robots (JE-FK-RS and JE-FK-Omni), attracting widespread attention. Ji Xiangyuan, Solutions Director of J-Elephant, explained, “The two new products we’re introducing today, JE-FK-RS and JE-FK-Omni, focus on two core pain points: high-bay dense storage and flexible adaptation across all scenarios.”

The JE-FK-RS achieves a lifting height of 11,000mm, adaptable to automated warehouses up to 12 meters high. Its 600kg rated load fully meets mainstream warehousing needs, while its 1,750mm aisle width saves over 30% of space compared to traditional solutions.

The other new product, JE-FK-Omni, redefines scenario adaptation with omnidirectional driving technology. Designed for high-density, low-bay environments, this product allows for zero-radius turns with a 1,750mm aisle width, saving 50% of aisle space compared to traditional solutions. Its 2,200mm lifting height perfectly adapts to scenarios with narrow passageways, such as low-bay warehouses and line-side warehouses, requiring efficient and dense storage.

Huiwen Unveiled Two New AMR Handling Robots

On October 28, Huiwen unveiled two new AMR handling robots on the first day of the exhibition – the iBen X100 and iBen X600.

The iBen X100 boasts a maximum payload of 100kg and a compact design, specifically tailored for confined spaces and highly flexible work environments. It is ideal for “goods-to-person” and “tote-to-person” handling scenarios. Its smaller size and greater flexibility allow for efficient material handling within confined areas, complementing other larger-payload models to create “shelf-to-person + goods-to-person” solutions, comprehensively covering light-weight material handling scenarios such as 3C electronics manufacturing, precision component assembly, pharmaceutical warehousing, and electronic pallet handling.

The iBen X600 features a maximum payload of 600kg, powerful motor, and stable operation. It is suitable for transporting medium to heavy materials, as well as for scenarios combining picking and handling of multi-specification and multi-size materials. It significantly reduces handling frequency and improves handling efficiency. The X600 meets the efficient handling needs of scenarios such as automobile manufacturing and bulk industrial material turnover, complementing the load capacity of models like the X300 and X100 to create a comprehensive intelligent handling solution covering light, medium, and heavy-duty scenarios.

MiMA Launched Counterbalanced AGV Forklift Body

MiMA launched the MKV50, a 5T dual-electric steering four-wheel counterbalanced AGV chassis. The MKV50’s biggest technological highlight is its innovative “dual-electric steering” design, which has successfully obtained two invention patents and three utility model patents. This system addresses the industry pain points of traditional heavy-duty AGVs—difficult steering and poor flexibility—by targeting the flexible steering and precise positioning requirements of 5T heavy-duty scenarios.

——————————————————————————————————————————————————————————————————————————————

From December 3 to 5, the Annual Conference on Mobile Robot Industry Development 2025 will be held in China. As an annual industry conference, this event will bring together over 500 companies and more than 1,000 participants from the mobile robot and humanoid robot industries to discuss the industry’s new future and directions from different perspectives. Stay tuned!

探索者论坛-scaled.jpg)