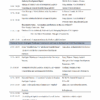

Today, AGiBOT announces a multi-million yuan project collaboration with FULIN P.M. Co., Ltd. (hereinafter referred to as “FULIN P.M.”). Nearly 100 units of YuanZheng A2-W will be deployed at FULIN P.M.’s factory. This marks the first large-scale commercial contract for embodied robots in the industrial sector in China and the first large-scale deployment of this type of robot in a global intelligent manufacturing scenario.

In July, AGiBOT and UNITREE also won the contract for China Mobile (Hangzhou) Information Technology Co., Ltd.’s humanoid bipedal robot contract manufacturing services, with a total budget of 124.05 million yuan (tax included). This order is the largest single purchase of humanoid robots in China. Among them, AGiBOT won the bid for a full-size humanoid bipedal robot with a budget of 78 million yuan (tax included).

FULIN P.M., located in Mianyang, Sichuan, is a leading company in the automotive parts segment. In recent years, its new businesses, including electric drive systems for new energy vehicles, thermal management systems, lithium-ion battery cathode materials for new energy vehicles, and key components for wire-controlled suspension systems, have experienced rapid growth. Its intelligent robot electric joint and component business has also begun to take shape.

The AGiBOT YuanZheng A2-W wheeled general-purpose robot, deployed at FULIN P.M.’s factory, is designed specifically for flexible intelligent manufacturing scenarios and can be widely used in various scenarios, including palletizing, handling, and loading and unloading of turnover boxes.

In July of this year, the first YuanZheng A2-W robot completed a three-hour live broadcast of routine industrial operations at FULIN P.M.’s production line loading scene, capable of delivering 1,000 cases of turnover boxes per shift.

This deployment of nearly 100 robots has expanded the application of robotic material box depalletizing and loading scenarios from “single-factory pilot verification” to “full coverage across multiple factories.” The robots’ operating range has expanded from the initial two production line locations to 15 loading points in the two core workshops of powertrain and reducer. They handle the daily delivery of raw materials for over 500 units, while also automating the collection of empty boxes, completing nearly 10,000 box moves per shift.

At the same time, this collaboration established a deeply collaborative system using “embodied robots + AMRs.” The embodied robot A2-W was responsible for picking and placing containers from multi-layer racks, while the AMR handled heavy-load pallet transport within the workshop. This not only leveraged the embodied robot’s versatile handling capabilities for containers and its adaptability to complex scenarios, but also capitalized on the AMR’s efficiency advantages in long-distance, high-load transport.

Wang Chuang, President of AGiBOT’ General Business Unit, stated that AGiBOT will use this project as a benchmark for the large-scale application of embodied industrial robots. The implementation path of “scenario penetration, data accumulation, and technological iteration” will provide a reference for more industrial scenarios, including automotive manufacturing and consumer electronics.

Note:

Logistics Automation Development Strategy & the 7th International Mobile Robot Integration Application ConferenceSoutheast Asia will be held in Concorde Hotel Kuala Lumpur, Malaysia on 21st August 2025. At the same time, the 2025 Global MobileRobot Industry Development Report will be released. Welcome to join us.

For agenda, please click https://cnmra.com/logistics-automation-development-strategy-the-7th-international-mobile-robot-integration-application-conference-southeast-asia-21st-august-2025-concorde-hotel-kuala-lumpur-malaysia/

For registration, please click https://docs.google.com/forms/d/e/1FAIpQLSdGHjpHRU0mR0_2ZlqtJpUV25s3XlIIHtkkUUfxz0W6vpBqiA/viewform?usp=header

探索者论坛-scaled.jpg)