The past decade has been a period of rapid development for China’s mobile robotics industry. Driven by policy guidance, market demand, and technological innovation, China’s mobile robot industry has grown from a weak base to a strong one, gradually forming a comprehensive industrial chain and ecosystem.

Over this decade, we have witnessed the rise and growth of countless innovative companies. We have also witnessed the deep integration and cooperation between domestic and international markets. Chinese mobile robot companies have actively participated in international competition and cooperation, continuously enhancing their strength and brand influence.

To more comprehensively and profoundly capture this magnificent development journey and provide a clearer insight into the future direction of the industry, we have specially curated a series of special reports on this milestone 10th anniversary. These special reports delve into the core development trends and valuable lessons learned from the industry’s development, focusing on products, companies, and individuals.

In addition, at the Mobile Robot Industry Development Annual Conference in December of this year, we will also release the 2015-2025 China Mobile Robot (AGV/AMR) Ten-Year Development Yearbook. Stay tuned!

In the decade between 2015 and 2025, China’s mobile robotics industry achieved a leap forward, expanding from traditional industrial manufacturing to a comprehensive range of sectors. Simultaneously, breakthroughs in artificial intelligence, sensor technology, and navigation have transformed mobile robots from simple transport tools into intelligent entities capable of autonomous decision-making and flexible collaboration.

During this critical decade, numerous mobile robot products have been released, representing not only the crystallization of technological innovation but also a vivid illustration of the industry’s development.

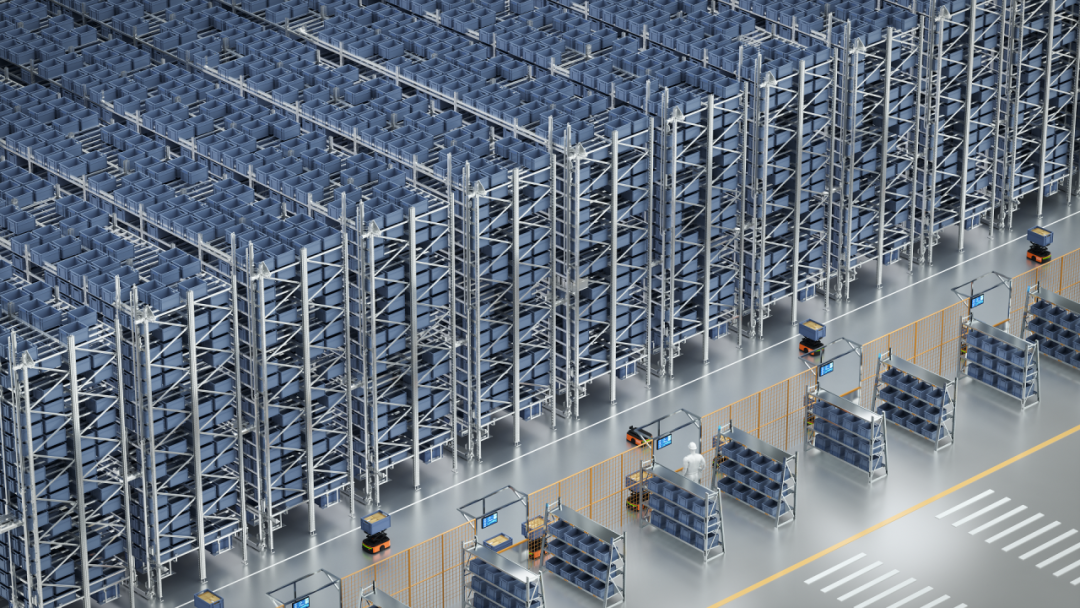

The Evolution of Warehouse Robot

From “Single Device” to “Global Ecosystem”

In 2003, Mick Mountz (former Webvan Logistics Director), Peter Wurman (Professor of the University of South Carolina), and Raffaello D’Andrea (Robotics Expert of ETH Zurich) founded Kiva Systems, aiming to reshape the warehousing model with robots.

In 2009, Kiva partnered with Quiet Logistics to deploy the first “goods-to-person” system, validating the technical feasibility.

In 2012, Amazon acquired Kiva for USD 775 million and reorganized it into the Amazon Robotics division, ushering in a new era of warehouse automation. Following the acquisition, Kiva’s technology rapidly expanded into large-scale applications.

Amazon’s acquisition brought Kiva, a new type of warehouse sorting robot, to the forefront in China and soon sparked a revolution in China’s mobile robot industry.

Geek+: One-Stop “Goods-to-Person” Picking Leads a Warehousing Revolution

In 2015, Geek+ officially launched its shelf-to-person picking robot, which is the first independently developed “goods-to-person” warehouse robot system in China. Geek+’s first Kiva-like warehouse robot was first deployed in Tmall Supermarket’s Tianjin warehouse during the Double Eleven (Singles’ Day) of the same year. In August 2016, Geek+ partnered with Vipshop to deploy an intelligent robotic system in its South China warehouse, marking China’s first large-scale application. This project validated the reliability of its warehouse robots in high-concurrency e-commerce scenarios, laying the foundation for subsequent market expansion.

Since then, Geek+ has continuously iterated its technology and upgraded its applications. In 2021, it officially launched the PopPick goods-to-person picking system, achieving integrated storage and picking for large, medium, and small items across all product categories for the first time. Its latest generation of PopPick shelf-to-person picking solutions utilizes a lighter-weight PopPick Lite workstation, improving picking efficiency by 67% compared to traditional picking methods while reducing workstation footprint by 50%, and optimizing space utilization and significantly improving efficiency.

In addition to the PopPick shelf-to-person picking solution, Geek+’s three star picking solutions include the SkyCube pallet-to-person picking solution, which utilizes a top-down storage and bottom-down picking model to improve space utilization, increase storage capacity by 5-8 times, and increase picking efficiency by 3 times compared to traditional manual labor. Furthermore, the RoboShuttle tote-to-person picking solution, renowned for its high storage capacity and flexibility, fully utilizes 12-meter vertical warehouse space and allows for spacing between totes as small as 20mm. This solution further optimizes storage capacity and offers exceptional flexibility, enabling multi-robot collaboration and the ability to dynamically add or remove robots without disrupting operations, flexibly adapting to customer needs.

Based on a deep understanding of diverse customer scenarios and dynamic market trends, Geek+ offers a comprehensive product line encompassing three major picking solutions, as well as intelligent sorting, handling, and smart forklifts to meet diverse needs. Furthermore, Geek+ utilizes a single system to coordinate all its robot models, enabling the creation of integrated solutions and complete warehouse solutions. This integrated robotics solution covers the entire picking, storage, sorting, and handling process, meeting customers’ diverse warehousing needs in one place.

Guozi Robotics: Picking Evolves from “Shelf-to-Person” to “Tote-to-Person“

In 2016, Guozi partnered with Staples to jointly develop the world’s first Picking AGV, obtaining an international patent and starting Guozi’s global business.

The Picking AGV utilizes a fork-type design, capable of locking onto five target totes at a time. Its freely rotating loading platform allows for turn-free operation, reducing aisle width to 1.2 meters. In 2020, it was upgraded to Picking Plus, boasting a lift height exceeding 4 meters and the ability to handle 5-8 totes at a time, which increased storage density by 40% and picking efficiency by over 30% compared to manual labor.

From the completion of the development of three Picking AGV prototypes in just three months in 2016 to the delivery and commissioning of nearly 300 Picking AGVs at Staples’ New York warehouse in just three months in 2022, Guozi’s products and services continue to evolve.

Currently, the Picking AGV family boasts a diverse product range, including double-deep, adaptive, and dual-stage gantry models, fully meeting users’ diverse storage and picking needs. GRACE Xpress, a full-process integration software, enables full process simulation before project implementation, fully simulating on-site usage and significantly shortening on-site delivery cycles. Intelligent adaptive location calibration, combined with deep learning algorithms, enables automatic calibration, allowing the Picking AGV to rapidly improve location accuracy during use and reduce operational maintenance burdens.

The success of the Picking AGV has fostered a strong strategic partnership between Guozi and Staples, with the two companies signing two strategic cooperation agreements. As the sole supplier of intelligent logistics equipment, Guozi has supplied Staples with over 1,000 robots, including Picking AGVs, to its warehouses in Minnesota, Los Angeles, Charlotte, Pennsylvania, Denver, and New York, spanning the eastern, central, and western United States. The Staples project successfully started Guozi Robotics’ global business. Building on its strong domestic presence, Guozi is now actively developing its overseas operations. The project has been implemented in numerous countries and regions across North America, South America, Europe, East Asia, Southeast Asia, and Central Asia, with large-scale use cases in over ten industries, including e-commerce, automotive manufacturing, heavy industry, and retail.

Hikrobot: The STRP solution redefines the efficiency and density of container-to-person picking.

In September 2024, Hikrobot officially launched the STRP solution at its “Commercial Warehousing and Distribution Special Launch Conference,” simultaneously introducing the STU robot and the next-generation Q1P.

The STRP solution primarily consists of the STU container-to-person robot, the Q1P latent robot, and the iWMS intelligent warehouse management system, leveraging the strengths of each product to achieve greater efficiency. The STU moves horizontally or vertically at high speed on the shelves, moving containers from high-bay shelves to lower container locations. The Q1P handles container for efficient picking. The STU has a maximum unloaded lateral travel speed of 3m/s and an unloaded longitudinal lifting speed of 2m/s; the Q1P has a maximum unloaded speed of 4m/s, significantly improving acceleration and deceleration performance, allowing two vehicles to switch positions in close proximity in just 2 seconds.

The STRP solution offers four core advantages. The first one is efficiency. STRP uses the STU to efficiently perform vertical container unloading operations within the aisle, effectively overcoming the throughput bottleneck of the CTU solution and significantly improving the overall efficiency and throughput. The second one is storage capacity. The STRP solution utilizes a high-bay racking design, resulting in a taller storage area and more compact aisles. Combined with hook-and-pull suction cup container retrieval technology, it minimizes container spacing and allows for multi-deep storage, significantly increasing warehouse capacity. The third one is greater flexibility. The Q1P performs bidirectional handling operations between workstations, providing flexible routing. The fourth one is continuous investment optimization. The overall investment in STU products, transportation, installation, and implementation is further optimized.

Hikrobot’s STRP solution, with its innovative “vertical container handling + horizontal docking” architecture, redefines the efficiency and density of container-to-person picking. Its core value lies not only in breakthrough technical parameters but also in empowering industries such as pharmaceuticals, e-commerce, and automotive through scenario-based solutions, achieving an upgrade from “single-point optimization” to “system reconstruction.”

From “shelf-to-person” to “tote-to-person,” and then to combined solutions, the evolution of warehouse robotics is essentially a continuous refinement of efficiency granularity. This evolution is not only a concrete manifestation of technological advancement but also a profound response to the logistics industry’s demand for refined operations, marking the advancement of smart warehousing from extensive automation to precision and flexibility.

In the continuous evolution of warehouse robotics, Chinese companies have not only made the leap from “technological imitation” to “scenario innovation” but have also reached every corner of the global supply chain with technologies more adaptable to complex scenarios, more cost-effective solutions, and a more open ecosystem. The rise of Chinese warehouse robot companies such as Geek+, Guozi Robotics, Hikrobot, Quicktron, and Hai Robotics has not only reshaped the global smart warehousing landscape but also injected new momentum into global logistics transformation with its “Chinese solution.”

Initiating the Revolution of Scenario Adaptation

Reshaping the “DNA” of Industrial Manufacturing

If warehousing logistics requires mobile robots to efficiently complete standardized handling and sorting, improving throughput through scaled, batch operations, in the manufacturing sector, dynamic adaptability in flexible production, precise process coordination, and tolerance to extreme environments become the core competitive benchmarks for mobile robots.

In 1991, the Shenyang Institute of Automation, Chinese Academy of Sciences customized China’s first magnetic stripe guided AGV for the Shenyang Jinbei Automobile Plant. It was used for material handling on the engine assembly line. This 2-ton device, powered by lead-acid batteries and guided by magnetic strips on the floor, achieved a speed of only 0.5 m/s and a positioning accuracy of ±10 mm. However, it marked a significant step forward in the transition of domestic mobile robots from the laboratory to the field. Starting with the automotive industry, over the past three decades, Chinese mobile robot companies have transformed from “followers” to “global definers” amidst the wave of manufacturing transformation, leveraging technological breakthroughs, deep application development, and ecosystem collaboration.

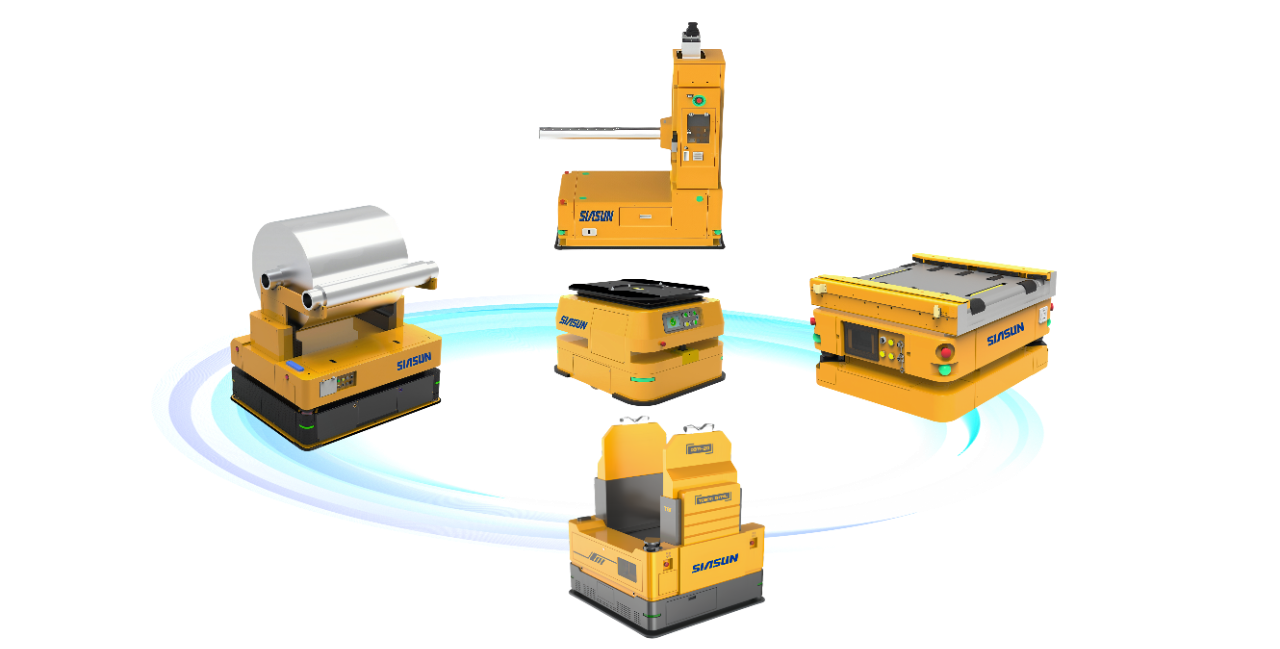

SIASUN‘s AGVs for the New Energy Industry: Breaking Through Foreign Technology Blockades and Achieving a Breakthrough in Domestic Product Production

In 2015, SIASUN Mobile Robots successfully delivered its first single-axis mobile robot, pioneering mobile robot applications in the power battery industry. In 2016, the first high-precision mobile robot (AGV) project, independently developed and delivered by SIASUN, was launched, marking the official adoption of domestically produced mobile robots in China’s power battery industry. Previously, the industry relied on imported equipment, which presented numerous bottlenecks. SIASUN has built a complete technology system encompassing core controllers, control systems, and more, achieving independent control of the entire AGV supply chain.

The SIASUN AGV-M-A series (double-lift V-groove) was developed to address the complexity of the front-end processes in lithium battery production and the limitations of traditional transfer methods. This product series, built on a high-load capacity, features a multi-degree-of-freedom omnidirectional motion system, integrating intelligent contour navigation and multi-navigation technologies to achieve high-precision repeatable positioning. Combined with intelligent path planning algorithms and a rich set of interface protocols, it builds an efficient and flexible distribution system. It covers full-process closed-loop transportation scenarios, including positive and negative electrode material distribution and empty coil core reverse flow transfer, helping companies improve logistics efficiency by over 40% and reduce labor costs by nearly 50%. Furthermore, through intelligent data statistical analysis, it becomes a precisely coordinated intelligent node in the flexible manufacturing chain.

Accelerating technological iteration is driving the deepening of SIASUN‘s global expansion: In 2019, the first generation of dual-lift V-groove AGVs completed machine docking optimization; in 2020, SIASUN achieved a breakthrough in overseas AGV exports for the new energy power battery industry; in 2021, the second generation officially launched; in 2022, the third generation completed performance upgrades; in 2023, it began mass delivery for large-scale domestic and international benchmark projects; in 2024, the fourth generation achieved large-scale deployment. From the first AGV deployed on a lithium battery production line to over 3,000 systems currently in operation, and from developing single products to delivering integrated system solutions, SIASUN has grown into a core leader in the intelligent logistics field of new energy power batteries. In this revolution in lithium battery intelligent manufacturing, each SIASUN mobile robot is a practitioner of “intelligent production” and a shining example of Chinese intelligent manufacturing going global.

EP XQE-122 Reach Stacker: Stacking Everything, Storing Everything

During the Double Eleven (Singles’ Day) 2024, EP launched the “W@W Digital New Warehouse” solution, boldly transforming traditional warehousing with the promise of “Stacking Everything, Storing Everything.”

EP’s Digital New Warehouse primarily consists of robotic lift trucks, standardized carriers, and a digital management system, suitable for a variety of businesses and warehousing scenarios. Taking the machinery manufacturing industry as an example, EP’s Digital New Warehouse enables companies to implement automated replenishment, automated night shift tallying, and automated inventory management without requiring any infrastructure renovation. This has reduced warehouse space by 40%, improved production line responsiveness by 50%, achieved 100% digitization of warehouse information flow, and achieved 100% inventory control.

This year, EP’s Digital New Warehouse underwent further upgrades, featuring the XQE-122 reach robot, creating a new aisle-free, intelligent, densely stacked warehouse. This warehouse features no fixed shelves, no boundaries, and supports stacking of various loads. This highly flexible warehouse can operate 24/7 and even tally items in the dark, significantly saving warehouse space and operating costs.

- The XQE-122 boasts a maximum lift height of 5.5 meters, a load capacity of 1.2 tons, and a battery life of up to 6 hours. It can easily handle both dense storage and high-frequency dispatching.

- The XQE-122 is equipped with EP’s proprietary 3D laser SLAM navigation system, utilizing a combination of top-scan lasers, an IMU, and a wheel speedometer to achieve centimeter-level positioning accuracy. It supports stacking operations up to 32 meters deep.

- The vehicle is compact in structure, requiring only a 2.9-meter aisle width to perform both loading and unloading operations. It operates at a maximum speed of 1 meter per second and can handle 10% slopes even when fully loaded, delivering stability and efficiency.

- It supports a variety of pallets, racks, guide carts, and plastic crates, and can adapt to pallet position deviations within ±10 degrees, enabling precise insertion and removal recognition, truly achieving “Stacking Everything, Storing Everything.”

- In terms of safety and intelligence, the XQE-122 boasts 360-degree sensing capabilities, with a forward recognition range of 20 meters and 5 meters to the left, right, and rear, respectively. It can accurately identify people, vehicles, and obstacles.

As the core carrier for EP’s Digital New Warehouse concept, the XQE-122 won the “Smart Stacking Architect Award” at the “World’s First Unmanned Forklift Scenario Application Competition” held in May of this year for its outstanding performance and innovative design. This product, through technological innovation, breaks through the spatial limitations and model barriers of traditional warehousing. Its aisle-free, densely stacked design significantly improves warehouse space utilization. Its multi-scenario and multi-carrier compatibility frees warehouses from reliance on fixed shelving, enabling flexible storage locations wherever demand arises. EP’s Digital New Warehouse, powered by the XQE-122, is adaptable to diverse production scenarios across industries, including machinery manufacturing, wine industry, food and beverages, automotive parts, and daily necessities, redefining efficiency and intelligence in modern warehousing.

Gyrobot Cobot: A “Safe Box” for Wafer Transport

Established in 2015, Gyrobot initially focused on technology research and development for semiconductor wafer handling applications. To meet the stringent cleanliness, vibration resistance, and high-precision requirements of semiconductor production lines, the team achieved breakthroughs in three core technologies: trackless navigation, dynamic stability control, and multimodal perception fusion. During this phase, Gyrobot completed the prototype development of its first intelligent trackless wafer handling robot and achieved ISO Class 3 cleanroom certification, laying the foundation for subsequent large-scale deployment.

In 2019, Gyrobot partnered with the world’s largest semiconductor packaging company to launch the “Smart Unmanned Factory” project. After two years of on-site development, Gyrobot secured 23 patents and achieved 11 industry certifications for its products, including arm and battery certifications, establishing its technological leadership in the semiconductor cobot field.

With the maturity of its technology and its growing industry reputation, Gyrobot entered a period of rapid expansion, continuously upgrading its product portfolio. The company launched its third-generation universal wheel AMR, featuring a width of only 60 cm, capable of operating efficiently in aisles as narrow as 0.88 meters and supporting the simultaneous handling of four FOUPs (wafer cassettes) or metal boxes. The company also incorporated large AI models into its robot decision-making system, enabling dynamic path planning and predicting abnormal events. For example, a Taiwanese customer’s factory used AI algorithms to improve the robot’s obstacle avoidance response speed from 200ms to 80ms, increasing production capacity by another 15%.

Gyroboto’s cobots have become a mature solution covering the entire process of wafer manufacturing, packaging and testing, and intelligent warehousing in the semiconductor industry. Their technological advantages and industry recognition have been widely validated by leading global customers. Currently, Gyroboto’s customer base includes mainland China, Taiwan, Singapore, Malaysia, Thailand, the Philippines, Japan, Mexico, the United States, and Europe.

Lanxin Robotics: The First 3D Vision Only Guided Mobile Robot (VMR)

In 2023, based on its leading core technology, LX-MRDVS® (Lanxin Mobile Robot Deep Vision System), and focused on automated SMT placement production, Lanxin Robotics officially launched the world’s first 3D vision only guided mobile robot (VMR). This product dispenses with all LiDAR sensors, instead utilizing 3D vision sensors and AI visual perception algorithms for positioning, navigation, obstacle avoidance, and docking. This product was recognized as “Zhejiang Province’s First Equipment” in 2024.

Product features:

- Equipped with a 3D vision navigation camera and AI visual perception algorithms, it intelligently captures natural features from the surrounding environment, converting depth images into point cloud maps. This eliminates the need for any manual markers, enabling markerless positioning and navigation for the mobile robot.

- 3D vision obstacle avoidance cameras are located on the front, back, left, and right sides of the robot, intelligently detecting overhead, low, static, and dynamic obstacles, enabling 360-degree obstacle avoidance. A proprietary AI visual perception algorithm understands obstacles at a semantic level and implements different obstacle avoidance strategies (stopping or circumventing them), ensuring safer and more intelligent operation.

- Utilizing a 3D visual positioning camera combined with an AI visual perception algorithm, the mobile robot achieves high-precision docking between the mobile robot and the SMT loading and unloading machine. Algorithm optimization has resulted in a docking accuracy of ±5mm, reducing the docking failure rate to zero and ensuring smoother loading and unloading.

- Eschewing the heavy appearance of traditional SMT robots, this product features an innovative structural design with a compact and lightweight body and a φ1,180mm rotation diameter, minimizing aisle space and enhancing its ability to navigate narrow aisles.

Lanxin Robotics’ release of the 3D vision only guided mobile robot (VMR) is the culmination of mobile robot companies’ continuous exploration of navigation technology. It also marks a milestone in the mobile robot industry’s transition from the laser era to the visual perception era. Since its official release, this robot has been widely used in SMT placement applications.

NTI Pioneered the Dual-station Counterbalanced Forklift AGV, Breaking the “Efficiency Ceiling” for Heavy-duty Handling.

Since 2000, NTI has partnered with international manufacturers such as Japan’s Daifuku and Finland’s ROCOLA to introduce AGV products and apply them to logistics systems, accumulating experience in AGV integration. In 2013, NTI launched the F2 series of laser-guided AGVs, developed in collaboration with Sweden’s KOLLMORGEN. Using laser navigation technology, the company transitioned from imported technology to independent R&D. In 2016, Shenzhen New Trend International Robot Co., Ltd, a wholly-owned subsidiary, was established to focus on AGV R&D, production, and system integration.

From system integration to independent AGV development, NTI is more closely aligned with its customers’ real needs. In 2023, NTI launched the first innovative dual-station counterbalanced forklift AGV in China.

This product utilizes a counterbalanced body with single or double forks automatically adjusting attachments. It can handle two or one pallet, with a rated load exceeding 3 tons, making it suitable for a wide range of automated handling scenarios for large quantities of materials. With a 3t payload, it can reach a height of over 5,300mm, with a maximum operating speed exceeding 1.5m/s and a positioning accuracy of ±5mm. It combines single- and dual-station pick-and-place functions, delivering handling efficiency far superior to conventional forklifts. Furthermore, advanced laser head lift and pallet vision recognition capabilities enable it to adapt to even more complex operating environments.

The dual-station counterbalanced forklift AGV, a domestic first, has been used globally as a model by Budweiser. Currently, NTI AGV products have been successfully delivered in nearly 300 projects across nearly 30 industries, earning widespread recognition from end users.

KUKA KMP Series: German Technology + Chinese Scenario Intelligence, Reshaping the “Convergence Paradigm” of Mobile Robots

In 2008, Kuka, a company steeped in German industrial heritage, set its sights on the Airbus heavy-duty project and began its AGV R&D journey in Europe, precisely addressing the enormous demands of automotive production lines and lineside handling. Just six years later, KUKA once again led the charge, pioneering the next-generation laser SLAM navigation technology and empowering it in the automotive industry, giving robots the “smart eyes” to autonomously avoid obstacles and flexibly plan in dynamic environments.

Technological evolution never ceases, and KUKA has keenly recognized the broader application space. In 2016, KUKA established its AMR R&D department and focused its hardware development efforts on the vibrant Chinese market. This has forged a high-speed channel for Sino-German technological innovation. In 2020, the KMP 600-S, the first AMR product jointly designed by the R&D teams of both sides, was released. In 2021, KUKA established its global AMR business headquarters in Shanghai and established a R&D and production base in Shunde. In the same year, it launched the KMP 600i, its first flagship product designed by a local Chinese team, which exemplified the deep integration of KUKA’s deep technological expertise and insights into the Chinese market.

The KMP 600i series is based on KUKA’s SLAM navigation technology and incorporates cutting-edge German SLAM algorithms. It boasts positioning accuracy within ±5mm, exceptional adaptability to dynamic environments, high flexibility, and high efficiency, requiring no complex on-site modifications. It is widely applicable in industries such as consumer electronics, new energy, automotive, white goods, pharmaceuticals, general industry, and e-commerce logistics. Its appeal lies not only in its core capabilities, but also in its exquisite styling and modular, standardized industrial design, which earned it the 2022 Red Dot Design Award for Best of Best, demonstrating KUKA’s unwavering commitment to industrial aesthetics.

From AGVs to AMRs, and strategically shifting from its European R&D center to its Chinese intelligent manufacturing hub, KUKA has continuously deepened its presence in the mobile robotics field, driven by continuous technological iteration and a resolute localization strategy. This not only clearly outlines the evolution of industrial automation technology from “fixed” to “flexible and intelligent,” but also profoundly reveals how a global industrial giant has achieved breakthroughs and leadership in emerging markets through technological integration and local empowerment.

Langyu’s Heavy-Duty AGV: Continuously Breaking Load Records

Since 2016, Langyu has focused on the “eight cutting-edge technologies” (servo control, wireless communication, synchronous hydraulics, etc.) for heavy-duty AGVs, integrating remote diagnostics and big data technologies. This has enabled Langyu to achieve the third technological revolution in industrial control computers, establishing technological advantages in drive unit hardware and multi-motor coordinated control software, laying the foundation for subsequent research and development. In 2018, Langyu decided to focus its resources on high-end, heavy-duty AGVs. In May 2020, Langyu launched its first independently developed 240-ton knapsack heavy-duty AGV, filling a domestic gap. In March 2023, it launched the world’s first 360-ton heavy-duty AGV, boasting a 50% increase in load capacity over its predecessor and a control accuracy of ±1cm.

In May 2024, Langyu’ newly developed 600-ton knapsack heavy-duty AGV officially rolled off the production line and was successfully delivered. It received positive customer reviews and once again broke the global record for single-vehicle heavy-duty AGVs held by Langyu. This heavy-duty AGV is 8.5 meters long, 4.54 meters wide, and 1.1 meters high. With a maximum load of 600 tons, it can reach a speed of 20 meters per minute, climb a 5-degree slope, and has a battery life of over 8 hours, with a recharge time of only 3 hours.

In January 2025, Langyu released the “Chuangyu,” the world’s first 300-ton omnidirectional outdoor unmanned AGV. Integrating Beidou navigation, laser SLAM, and AI decision-making technologies, it achieves millimeter-level positioning and autonomous obstacle avoidance in complex road conditions, filling a gap in outdoor heavy-duty logistics.

Looking back at the development of China’s AGV/AMR industry, from the first domestically developed AGV application in 1991 to Amazon’s acquisition of KIVA in 2012, which triggered a boom in e-commerce sorting AGVs, to around 2015, with the rise of artificial intelligence and robotics, and the growing demand in manufacturing, logistics, and warehousing, the Chinese AGV/AMR industry experienced explosive growth, ushering in its “golden decade.” These 10 classic products from the past decade have evolved from simple material handling to integrating cutting-edge technologies like AI, visual recognition, and big data, enabling autonomous decision-making and efficient operations in complex scenarios. China’s AGV/AMR industry has achieved remarkable success, with product performance continuously improving and its application areas expanding from e-commerce warehousing and manufacturing to healthcare, agriculture, ports, and many other sectors.

Looking ahead, with the continuous advancement of technologies like 5G, artificial intelligence, and the Internet of Things, the AGV/AMR industry will usher in even greater development opportunities. Products will develop towards greater intelligence, flexibility, and lightweight, and collaboration between different product types will become increasingly integrated, forming a more comprehensive intelligent logistics and production system. At the same time, industry competition will intensify, requiring companies to continuously increase R&D investment, enhance technological innovation capabilities, and improve product quality to gain a foothold in the market. It is believed that with the concerted efforts of all parties, China’s AGV/AMR industry will continue to write a brilliant chapter.

Note:

Logistics Automation Development Strategy & the 7th International Mobile Robot Integration Application Conference Southeast Asia will be held in Concorde Hotel Kuala Lumpur, Malaysia on 21st August 2025. At the same time, the 2025 Global MobileRobot Industry Development Report will be released. Welcome to join us.

For agenda, please click https://cnmra.com/logistics-automation-development-strategy-the-7th-international-mobile-robot-integration-application-conference-southeast-asia-21st-august-2025-concorde-hotel-kuala-lumpur-malaysia/

For registration, please click https://docs.google.com/forms/d/e/1FAIpQLSdGHjpHRU0mR0_2ZlqtJpUV25s3XlIIHtkkUUfxz0W6vpBqiA/viewform?usp=header

探索者论坛-scaled.jpg)